Don’t ask, “Can we take the order?” Ask, “Should we?”

(Is that order profitable to promise?)

Available to Promise software (ATP) and Capable to Promise software (CTP) aren’t enough in today’s tumultuous business environment beset by chronic supply shortages; you need to consider profitability in your order processing to make the best business decisions.

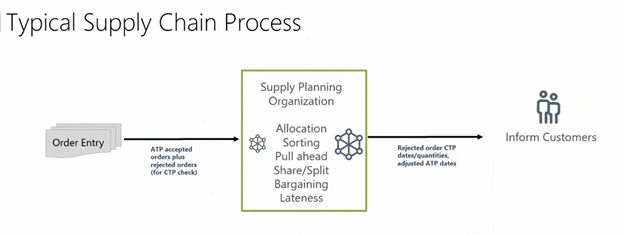

Consider an order-taking process that enforces ATP alone.

Even with real-time ATP at order entry, all orders flood into the supply planning organization with the expectation that those orders that surpassed ATP quantities need to be analyzed. Following that, customers must be informed of decisions made regarding how much product they’ll receive and by when.

The logic applied, assuming there is some beyond “squeaky wheel gets the grease”, is often stored in a non-integrated system, and is at risk of being overridden. Many of the rules applied are inconsistent and changed frequently. This is a time-consuming process that never improves with repetition, and it delays providing customers with updated information which ultimately hurts customer satisfaction.

Accelerate Decision-Making

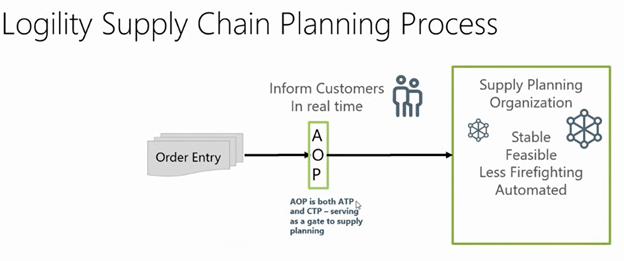

The Logility® Digital Supply Chain Platform offers a solution that improves upon this: guesswork is removed, accelerating the decision-making process and ensuring you maximize financial outcomes. Using a methodology that combines ATP and CTP, your own production capacity and your supply chain production capacity can be checked immediately, at the time an order is placed. This leads to less firefighting and increased productivity.

We call this powerful combination automated order promising (AOP). AOP serves as a gatekeeper to the supply planning team. The solution checks against available stock plus capacity, material availability, alternate sourcing scenarios, and other constraints as needed. With AOP, your salespeople and e-commerce platform have accurate, real-time estimates of how much product is available to promise or capable to promise so orders will never go unfulfilled due to lack of available inventory.

Here are some key advantages of an automated order promising solution:

- Improved customer satisfaction. By automating order promising, you can provide real-time insights into which products are, and can be, available.

- Better decision-making. With automated order promising, you can better understand supply and demand across your product line. Armed with these insights, you can make fast, informed decisions to continuously improve operations.

- Time and cost savings. AOP helps identify ways to speed up your supply chain processes. Plus, you can use the solution to explore ways to lower supply chain expenses, at the same time accepting more inbound orders with significant time saved.

- Effective risk management. The solution ensures your teams can always access real-time product inventory information and perform what-if analyses to prepare strategies for sudden shifts in product demand.

Elevate Decisions and Protect Margins with PTP

But what about simultaneously protecting margins? ATP and CTP are insufficient functions in a world of constant disruption and tight supply. Profitable to Promise (PTP) is a natural extension of the order promising and sales and operations planning processes.

Profitable to Promise elevates the decision from, “Can I take the order?” to “Should I take the order?”, where the decision criterion is not restricted to the profitability of the order under scrutiny, but the relative profitability of forecasted orders and other demand alternatives. In other words, it allows planners to ask, “Should I take this order now or preserve my scarce resources and capacity for a future order with much higher margin potential?” Service level agreement compliance and profit maximization can be balanced and trade-offs analyzed.

How does it work? At the point of committing to an order, Profitable to Promise allows companies to compare the realizable profit from an actual customer order to the opportunity cost (profit) associated with a forecasted customer order that may consume the same resources. This capability moves beyond current ATP and CTP capabilities and requires an integrated digital supply chain platform.

The Logility platform accelerates the sustainable digital supply chain by leveraging analytics and artificial intelligence to empower your business with greater visibility for faster decision-making. That means more accurate planning, accelerated cycle times, improved precision, and increased operating performance. Reach out to our specialists today to discuss our supply chain solutions.