Reach corporate social responsibility goals while improving your economic sustainability.

Key Takeaways:

- You make important decisions daily that affect both your own corporate responsibility goals and external ESG demands from consumers and investors

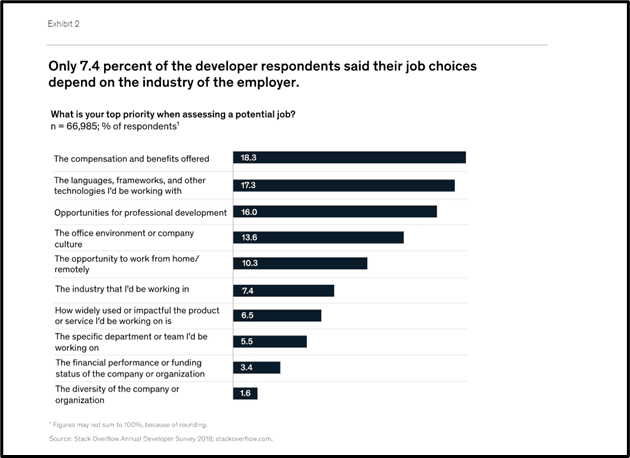

- Vendors can make or break your broad supply chain goals, which makes real-time, AI-analyzed data essential for supply chain decision-making

- Self-reporting and a cumbersome audit process present dangerous challenges that can be overcome with an integrated platform

- To supply the detailed reporting required by all stakeholders, complete transparency into your entire supply chain is needed

- One bad vendor decision can damage your brand beyond repair, so constant vigilance and swift action are necessary

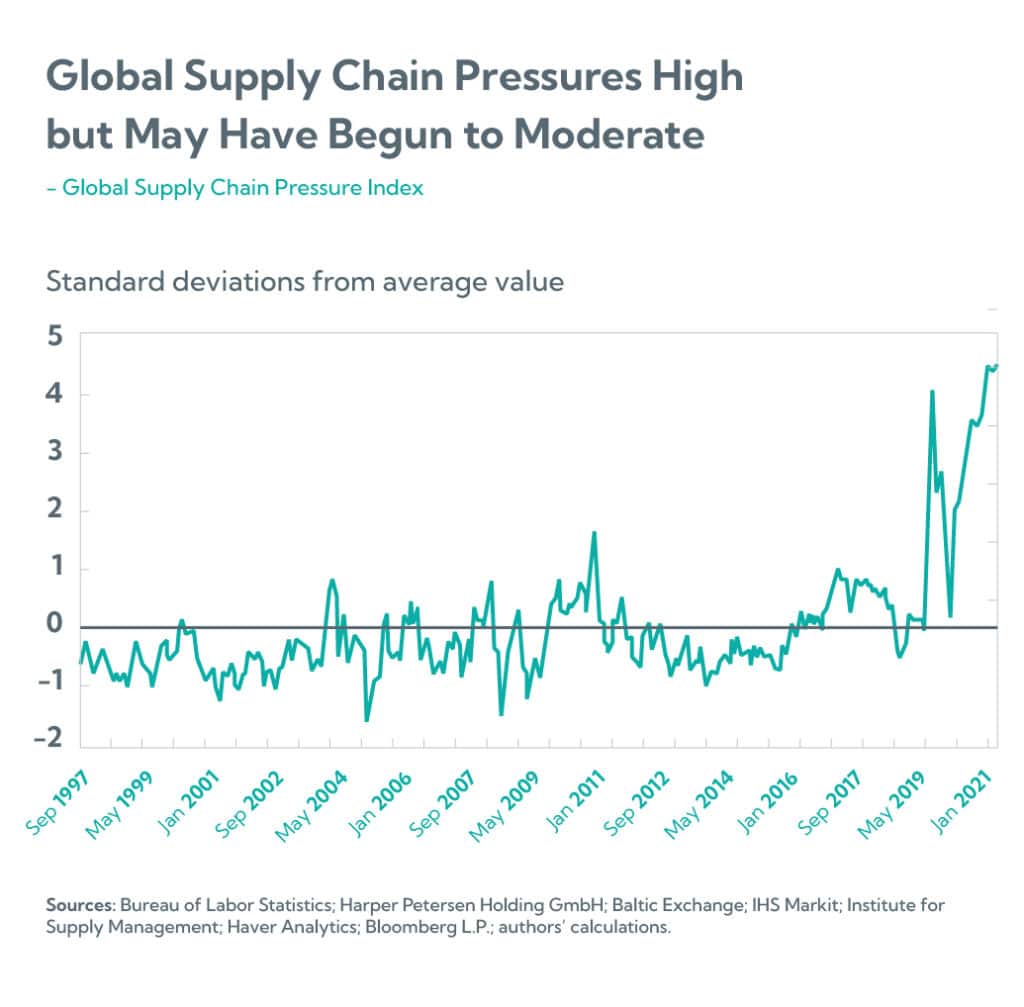

Supply chain executives make vital decisions daily. Disruptions – from wars to COVID-19 lockdowns to a lack of containers – just add to what is already a complex undertaking. A holistic approach using reliable, properly analyzed data is required to achieve both your business and corporate responsibility goals.

Data is useless if it’s not actionable. True corporate social responsibility (CSR) requires vigilance and compliance throughout the entire supply chain, and this takes properly analyzed data. This is especially important in vendor management. Your vendors can be your greatest strength or a source of serious liability. When it comes to supply chain decision-making, you need a digital corporate responsibility solution.

Ethics and sustainability affect brand value, and corporate responsibility in the supply chain is a huge part of this. Supply chain leaders who understand public concerns about the environment, health, and safety know that nothing affects this equation as much as their vendors.

Do your vendors present environmental, regulatory, or other risks to your company values? Can you trust their self-reporting? What about a vendor’s location or other factors that might affect their performance? With so many unknowns plaguing your supply chain decisions, this is one area where the right data and AI-supported analysis means you can move forward with confidence.

Socially Responsible and Economically Sound

A sustainable supply chain is no longer an option, as both consumers and investors clamor ever louder for brands to up their game when it comes to environmental, social, and corporate governance (ESG). They want to know where everything comes from, its environmental impact, and that it was produced by people who are treated fairly and humanely.

You want all of this, too, but you might not be sure how to get there, especially in an era of such profound uncertainty. You must be sure that the decisions you make don’t just work for today but will continue to work in the future to meet your economic goals. The economic sustainability of your company is at stake as much as anything else.

Uncertainty aside, even in times of relatively smooth supply chain operation, you never know what’s coming up next. But you can probably guess that new compliance standards and regulations are likely. Consumer demand is sure to rise. Trade embargoes will follow political turmoil. Not only do those factors put your reputation on the line, but they can also damage the viability of your enterprise.

Fortunately, there are powerful digital solutions that can give you the actionable information you need to both accelerate and improve your supply chain decision-making.

Enhance Financial Performance, Boost Reputation, Strengthen your Supply Network

Data confidence is everything as ESG demands become an integral and inescapable part of supply chain decision-making. It is imperative that companies build stronger and more sustainable supply chain networks. This can only be done via better management of governance assessments and audits, which then fuel better, sustained collaboration with your entire vendor network.

Audits are vital but time-consuming, incredibly inefficient, and error-prone – often facilitated by an exchange of emails. Self-reporting has its own unique set of issues. What’s required is a digital solution that offers easy integration, storage, and the analytics you need to achieve transparency, sustainability, and better supply chain decision-making.

Your corporate responsibility solution should:

- Surface variants between audit findings and self-reported scores and analyze the results

- Issue corrective action plans and adjust your sourcing plans in real time with consideration of a supplier’s progress toward sustainability objectives

- Offer reports that allow you to publicize practices and findings to all stakeholders with full transparency and confidence.

The right platform will give you a single source of supplier data you can use to assess vendor compliance. Because form numbers and identifiers vary, seamless mapping of data is required to ensure you’re viewing the same information without having to cross-reference multiple systems.

You’ll want to be able to collect factory certifications as well as manage all ESG-related assessments. As CSR has become subject to more mandatory regulations, self-regulation is no longer possible, which makes data-driven supply chain decision-making mandatory.

It is incumbent on organizations today to make sure they have the information they need to plan, schedule, and perform multiple assessments. Further, you want to be able to capture and evaluate the results so you can generate improvement plans. This allows you to remediate issues, assist supplier-users with training, and craft an exit plan to shift non-compliant suppliers out.

All of this results in stronger supply chain partners who will appreciate a fair and efficient system that motivates them to adopt best practices, knowing that compliance is the key to retaining your business.

It’s a Matter of Long-Term Value

A digital solution to corporate responsibility has a positive impact on the world, but it also supports your long-term business growth. Compliance standards must be met, consumer demands fulfilled, and investors satisfied. Greenwashing is unacceptable. Transparent, verifiable reporting is essential.

A non-sustainable supply chain exposes your company to avoidable business risks, including damage to your brand reputation and foreseeable supply chain disruptions. The data gleaned from a transparent supply chain will optimize your business planning as well as streamline product movement and balance supply and demand for inventory.

Ultimately, sound supply chain decision-making that supports all the requirements of the ESG enterprise requires data and AI analysis supplied by the right digital supply chain platform.

Sound, Sustainable, and Profitable Supply Chain Decisions Start with Logility

Logility provides the supply chain platform that allows you to trace sustainability through all tiers of your sourcing. Our platform utilizes AI, machine learning, and automation to help easily track and analyze your supply chain, so you always have optimal performance and key insights. Make better decisions and make more profits. Contact us today.