It’s time to evolve your supply chain from one-size-fits-all to purpose-built. Start your journey with the top six use cases for network optimization.

Do your business leaders believe they’ve locked down your supply chain network with the right partners, processes, technologies and contingencies that can overcome next week’s challenges as well as next year’s? This belief may be fraught with risk. A potent combination of incorrect assumptions, changing business needs and unforeseeable disruptions will eventually degrade the network that has been painstakingly created, resulting in supply chain rigidity, sluggishness, missed opportunities and higher costs.

Now, consider a different vision for how a supply chain can be designed and how it can operate. Instead of placing a premium on hedging against an unpredictable future, think about having, at your fingertips, the ideal supply chain for fulfilling your next order. And then a different but still ideal network for the following order – ideal in the sense of the optimal balance of cost, speed, risk mitigation, growth, customer satisfaction and meeting environmental, social and governance commitments.

It’s time for business leaders to let go of traditional assumptions, processes, and decision-making behaviors and start restructuring their operations to achieve maximum efficiency and flexibility. Fortunately, the necessary technology exists today.

Answer Your Toughest Network Design Questions

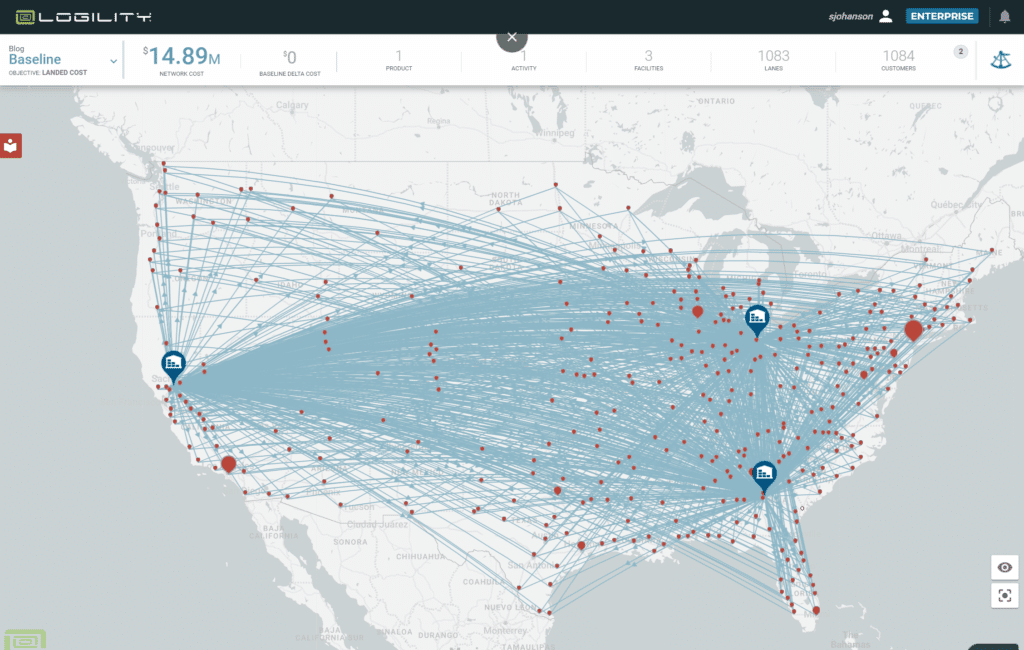

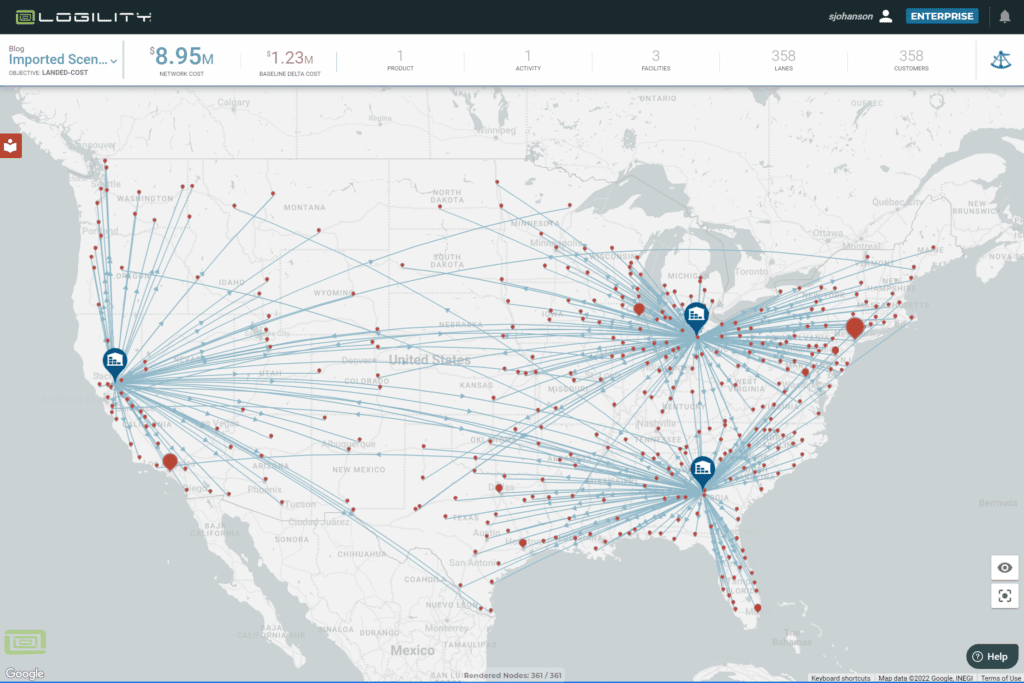

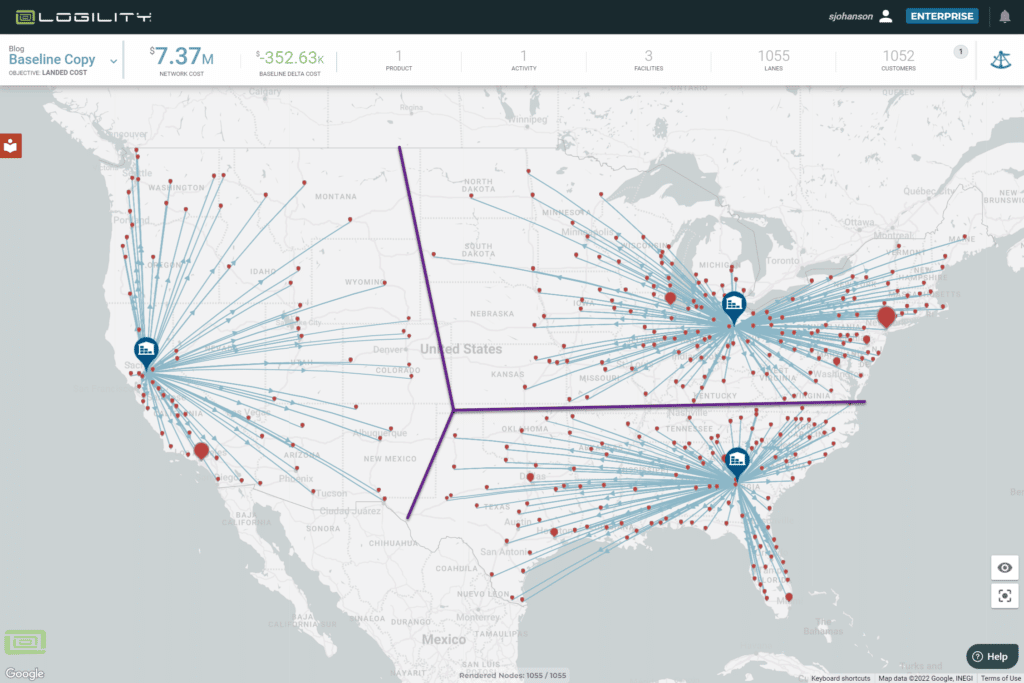

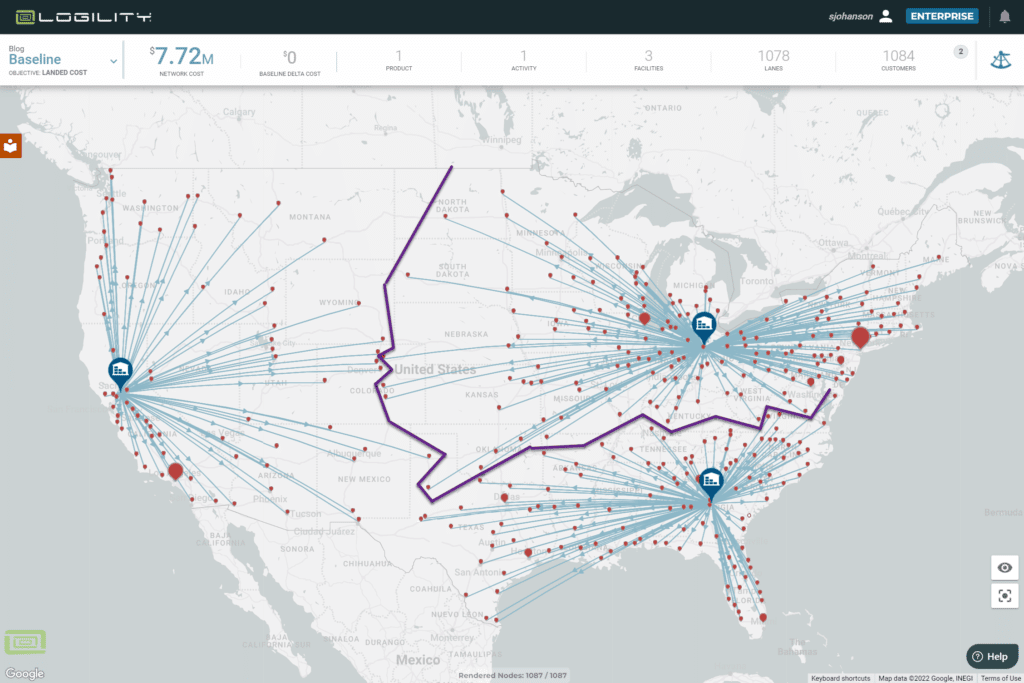

Network optimization puts continuous supply chain design at your fingertips with an intuitive, usable interface that lets you and your own people (rather than hired consultants) configure and explore design alternatives continuously. Powerful scenario analysis identifies optimal locations for future plants, warehouses or 3PL locations and quickly presents impacts to cost and service in an interactive environment.

Check out the 6 top uses cases for network optimization below.

- Manufacturing Analysis: Optimize the total landed costs of production decisions. Balance your capacity constraints and operational requirements in one model. Determine the optimal scenario that minimizes total production, freight, inventory costs and meets service requirements. Truly understand the impact of near-shore and off-shore scenarios. Case in point: a consumer electronics company made a critical off-shore/near-shore decision and determined that the long-term risk and operational impact of near-shoring in Mexico outweighed the cost advantage of production in China and Vietnam.

- External Finished Good/Raw Material Supply Analysis: Use network optimization to build tariff costs and supplier capacity shortages into your impact analyses.

- Emerging Market Analysis: Build a roadmap and playbook that addresses the trade-offs based on shifts, dips and spikes in demand. Use cost-to-serve analyses as part of evaluating the profitability of entering and exiting markets. Build “optionality” into your supply chain by designing in ways to grow, expand, or react to variability.

- Disruption Response: Don’t just react to a supply chain emergency—treat emergent disruptions as a chance to think strategically about your logistics network. Model the new flow paths around a port slowdown or a supplier’s capacity shortages. Understand the total impact of new routes and identify the optimum supply and logistics partners. Case in point: an industrial goods importer modeled the impact in time and cost of bypassing Long Beach during a slowdown by delivering to a Mexican port and directly railing containers to the central U.S.

- Logistics Analysis: Identify ways to trade expensive modes and services for faster and more profitable ones. Understand and quantify the viability and benefits of solutions such as pooling, delaying strategies, and 3PL and 4PL offerings. Case in point: a German-based appliance manufacturer re-designed their US network to take advantage of consolidating import operations into a limited number of ports but also maintained a complex parts and service network.

- Distribution Network Strategy: Explore and design aggressive distribution strategies that balance cost and customer service goals. Examples include optimizing the flow and profitability of an existing market, determining how and where to employ omni-channel techniques, and taking advantage of new technologies like on-demand warehousing or fulfillment services. Case in point: a mattress eCommerce company designed a supply chain to manage explosive growth and identified zone skipping as a risk-proof way to expand and save 33% on their last-mile costs.

By enabling a comprehensive approach to continuous, repeatable network design, network optimization helps realign organizational goals by reframing decision-making as an opportunity to fulfill demand more profitably.

This new decision-making paradigm helps avoid the traps and limitations of functional approaches to cost reduction and efficiency gains. Now, you can visualize an optimum network, communicate a future state to your organization, and rapidly drive to decisions and action.

Talk to Logility’s supply chain experts today – we are ready to help you answer complex questions and make faster decisions with network optimization. Or see the solution in action here.