Competing for the eCommerce supply chain with supply chain modeling software.

eCommerce — the Disruptor

eCommerce and its progeny, omni-channel, have both cleansed and complicated the supply chain world: cleansed in that inefficient operators and operations have been eliminated through the reduction of barriers to competition; complicated in that the survivors are in a constant state of evolution.

The dream of the digital economy reaches its high tide mark when put against the physics of time, distance and mass. Even industries that are moving to 3D printing are faced with shipping printers, materials, and replacement parts — you cannot print a replacement part for a 3D printer if the printer is broken.

Most companies now face the “one-day challenge”. How can they economically get their product to their customers one day from the order?

Here’s the easy way — pay someone else to stock and deliver your product. They will take the profit and you will be left with the risk and the inventory holding costs.

What is Practical, What Can You Do?

From process to approach — the one-day challenge takes these four steps:

1. Identify the types of nodes that can service your supply chain — get creative, this is the 21st century and new models for logistics are arising constantly.

2. Build a model of your demand — this you can do easily from your history, or forecasts, or demand proxies.

3. Draw that curve of cost vs. service time — here is where you need to get analytical. Read on to see how.

4. Gather the leaders in your supply chain and pick a strategy based on hard numbers.

The faster you can move through these steps, the faster you can effect change. And the faster you change, the earlier you realize a performance improvement.

Step 1 — Look at Inventory in a Different Light

Traditional warehouses are a good starting point. But they are clumsy — they are a fixed size, come with a fixed lease period, and take time to set up and shut down. But they are still the anchor of an omni-channel strategy. You can also look to other ways to supplement these. Here you can get creative:

- Any store that stocks your inventory is already halfway to a fulfillment center

- Partners and suppliers can also serve as fulfillment centers

- Look to flexible stocking locations and dynamic warehouse providers

- Ask most of your logistics companies and they can provide a fulfillment solution.

All of these sites can serve as candidates. This step is not about narrowing down your options but opening them up. Some might seem impractical now, but when you put them up against your overall strategy, total landed costs, and the value of delivering to your customers faster, they might become viable.

Step 2 — Find Your Customers

This should be the easy step. Simply run next year’s forecast or last year’s shipments to customers and you have destinations by postal code. Remember to capture all the elements related to your product, most importantly the average shipment size by gross weight or dimensional weight.

If you are a growing or changing your business, you might want to look at this differently. Shipments for eCommerce operations are rarely the same from one year to the next. If you have not “settled” into your market, you might find that your demand is heavily weighted towards one geography or another. Maybe marketing started in one place or promoted in another. In these cases, look for a proxy. Population is always a good one as almost every good will regress to population.

Step 3 — Find the Trade-Off Between Fulfillment Centers and Service Time

Now we are going to roll up our sleeves. In traditional network design, you might be spending hundreds of thousands of dollars on a consulting project, and this project might take you three to six months. But eCommerce is not like that; you need to look at your supply chain dynamically. By using solutions and methods that are agile and fast, you can do this analysis quarterly, monthly, even weekly if required. Logility’s network optimization solution is just that simple. With built-in data and best practices, you can:

- Load up a set of demand from your forecast or shipment history

- Add in the potential candidate locations

- Solve for the best mix of fulfillment locations, warehouses, partners.

And quickly put numbers to:

- Cost

- Service time

- Inventory levels

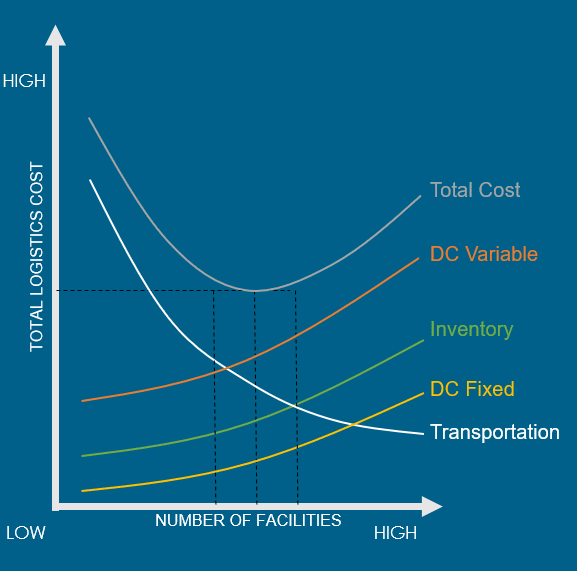

You should be able to build a set of curves like this and then quickly modify scenarios around it:

Step 4 — Drive to a Decision

Here is the key – with powerful supply chain modeling software that can quickly spin out viable scenarios and calculate their cost and service tradeoffs, you can sit in a conference room with your organization and quickly drive towards a strategy. Identify what you want to do today, next month, next year.

Using Logility’s network optimization solution will take the ambiguity out of making optimization decisions. You can quickly drive to the right balance of cost and service time. Then you, as a progressive supply chain leader, can direct the conversations towards:

– What approach would contribute to the bottom line?

– How do we build in change and resiliency?

– How can we change faster and be more agile?

Logility is there to make you look smarter.

Interested in understanding how center-of-gravity studies are not optimal network optimization strategies? Read more here.

Written by

Steve Johanson

SVP Industry Principal

Short bio

Steve Johanson is the SVP Industry Principal for network optimization at Logility, where he draws on 25 years of helping clients optimize their supply chains. Steve works with the Logility team to bring new and innovative solutions to the greater supply chain community and to help the client base build skills and knowledge to sustain competitive advantage.