Supply variability today. Where are we at?

It’s tempting to think of supply variability as a recent phenomenon caused by COVID-19. Supply chain professionals know better. Supply disruptions are as old as trade itself. But the disruptive power of the pandemic was off the charts, as they say.

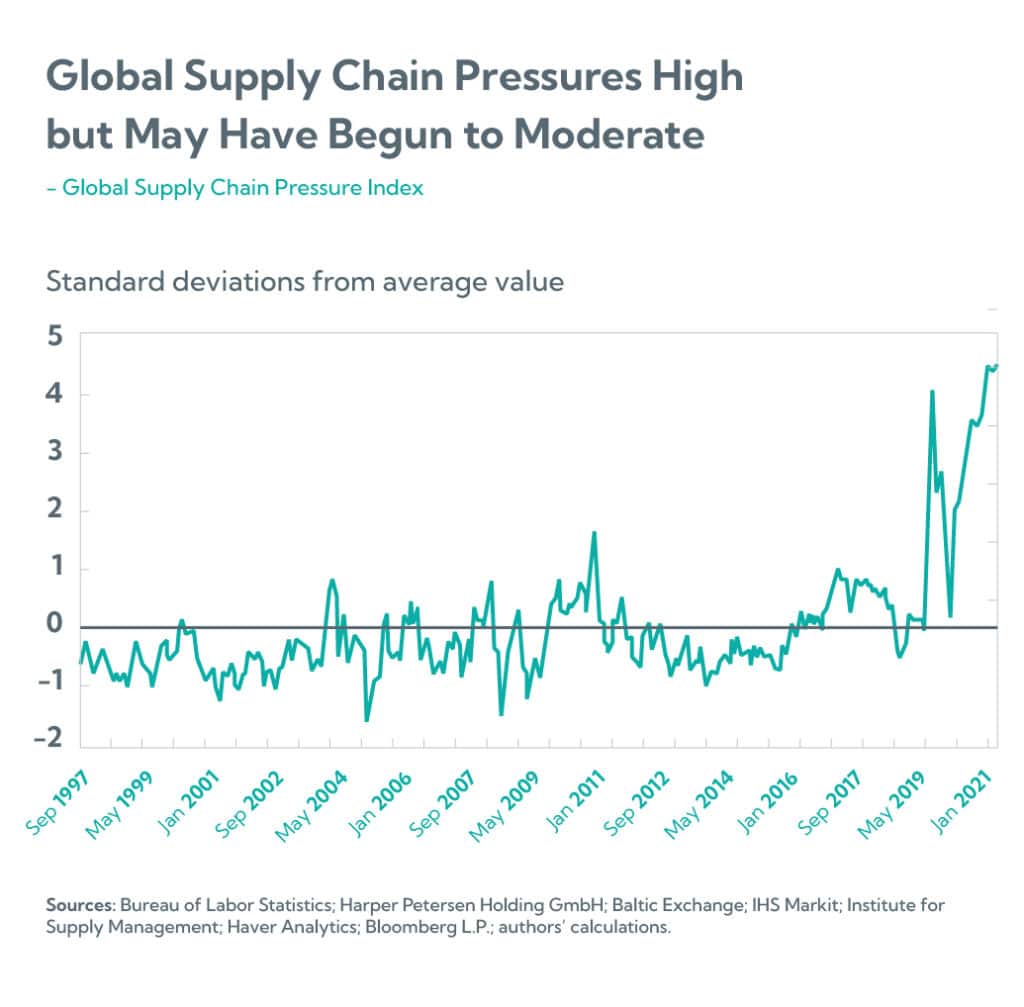

How far off the charts? Depends on the data, of course. Let’s take a look an “index of indexes” recently devised by The Federal Reserve Bank of New York. The Global Supply Chain Pressure Index integrates commonly used measures “with an aim to provide a more comprehensive summary of potential disruptions affecting global supply chains,” the authors said in a post on the New York Fed’s website.

The new index is comprehensive, synthesizing data from a variety of sources including the Baltic Dry Index (cost of shipping raw materials), the Harpex Index (container shipping rate changes), Purchase Manager Index surveys and data from the Institute of Supply Management’s manufacturing survey.

Note the magnitude of the COVID disruption. The index is scaled by its own standard deviation. You’ll (perhaps) recall from stats class that in any distribution, about 95% of values will be within two standard deviations of the mean. The Pressure Index registered ~4 at times during the past two years.

Averaging across industries, companies can now expect supply chain disruptions lasting a month or longer to occur every 3.7 years, and the most severe events take a major financial toll.

McKinsey, August 2020

What’s the Smart Response to Ongoing Supply Variability?

Supply chain professionals continue to wrestle with supply problems as we emerge from the pandemic. To address ongoing supply-side turmoil, Logility recommends:

- Building and achieving a feasible plan and the importance of “what-if” analysis capabilities. It starts with defining “feasible” and establishing clarity of roles so the ‘top floor’ and the ‘shop floor’ are synchronized;

- Focusing on the form and function of inventory to maximize the utility of the buffer. That means understanding inventory positions and capabilities from raw materials through semi-finished goods to in-transit finished goods; and

- Ensuring adherence to the schedule, which requires understanding constraints across the entire supply network.

This post focuses on #1 above: the importance of “what-if” scenario planning capabilities. In a single-source world, “what-if” scenario planning would be largely irrelevant. It’s true that some companies argue for a smaller number of highly competent, reliable supply partners, especially in the context of achieving sustainability goals. But few argue for single-source. The risks are too large. In fact, a growing number of businesses are ditching single-source supplier agreements to hedge against global events that disrupt supply lines.

As a result, multi-sourcing is gaining popularity as a purchasing model. Driven by organizations that seek to mitigate risk as well as capitalize quickly on market opportunities, multi-sourcing offers clear advantages, including reduced risk of supply shocks and ongoing, healthy competition among vendors across a variety of factors like innovation, price, service level agreements (SLAs) and willingness to share risk.

We Can’t Always Know What, But We Can Know What If?

Paraphrasing a popular Logility blog post, uncertainty isn’t a license to do nothing. We’ve entered an era in which businesses must be hyper-vigilant – anticipating risks, disruptions, and opportunities – while on the journey to build a resilient enterprise.

By asking “what if?” inside a data-driven framework, leaders can evaluate strategic and tactical sourcing options. Moreover, when built on a digital model – or digital ‘twin’ – of the supply chain, integrated business planning can leverage “what-if” intelligence to find the optimal balance between supply and demand, as well as risk and reward. Technology-enabled “what-if” analysis and scenario planning can provide on-demand forecasts so organizations can optimize plans as often as required. Supply chain readiness can be evaluated via real-time simulations, yielding improved visibility throughout the extended enterprise. Financial performance can also be assessed and compared against plans from multiple perspectives simultaneously.

From Defense to Offense

By examining the possibilities of every conceivable scenario, decision-makers can not only minimize the impact of future shocks, but discover more long-term opportunities for growth. What begins as a means to mitigate supply chain chaos becomes a method for spotting a silver lining and acting on it. This is the beauty of “what-if” analysis and scenario planning, whether in times of crisis or calm somewhat less crisis.

Read more about the benefits of a diverse sourcing strategy here.