(Or a cautionary tale about cutting corners.)

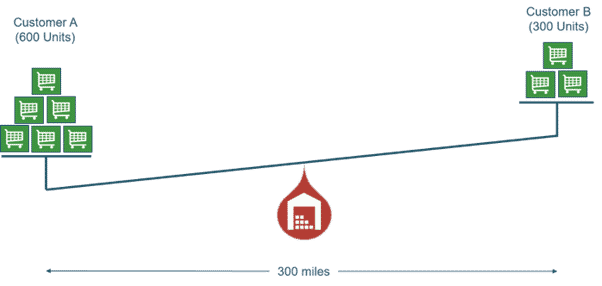

Are you helping your teenagers with their SAT preparation? Here is a good test question: You have two customers 300 miles apart. Customer A has 600 units of demand and Customer B has 300 units of demand. Where is the best place to put a distribution center?

What is your answer?

a) In the center, 150 miles from both customers

b) 100 miles from A and 200 miles from B

c) 200 miles from A and 100 miles from B

d) At Customer A

e) At Customer B

f) None of the above

The classic center of gravity analysis in this case will tell you that answer (b) should be correct — the weighted center of demand is one-third of the way from A to B. But you, as a logistician, are not trying to find the center of demand; you are just trying to find the lowest cost solution. And that is answer (d) — put the warehouse at Customer A’s location and then ship 300 miles to customer B. This answer minimizes the net unit miles shipped.

We all wish logistics problems were so simple, but when we complicate the network, we can often lose the picture of what we are trying to accomplish. Here we see the classic paradox of center of gravity studies — they are simple and believable, but they are only a proxy for what the logistics expert is trying to optimize: cost and service time.

What Makes Center of Gravity Popular?

Simplicity! The time, cost, and effort of doing a classic network design project can be prohibitive. These studies have historically required complicated and hypersensitive software, the studies last for multiple months, and they can cost in the hundreds of thousands of dollars.

Many logistics experts fall back on a center of gravity study to do routine network optimization such as a warehouse location selection. They are fast and provide understandable results. In fact, center of gravity studies have become an industry-accepted practice because they are perceived to be “good enough”. However, these models are inherently wrong.

How Do These Studies Make Errors?

Any model is merely a proxy of the future. And a fundamental assumption for center of gravity is that direct-line distance is a good proxy for cost and delivery time. However, total cost and delivery times have multiple variables that are not completely correlated with distance:

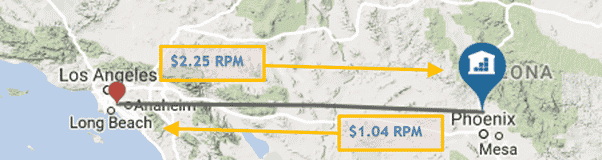

Problem # 1 → Market costs are very different by area and direction: The actual rate-per-mile for truckload carriers may vary by as much as 3X or more. Some markets such as Los Angeles are net exporters — more trucks go out than in. Shipments into Los Angeles can be very low cost. Long haul costs can be as low as almost $1/mile and short haul distances can be as much as $4/mile or more if they are subject to minimums. Therefore, weighting distance can be very misleading.

Example 1: A recent quote from Phoenix to LA and from LA to Phoenix shows more than a 2X difference in the rate per mile (rpm) for one direction over the other.

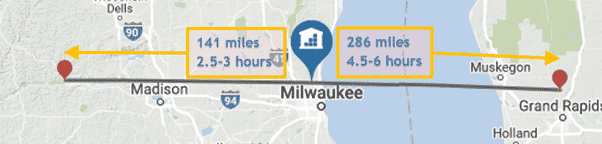

Problem #2 → Distances and drive times are subject to geographical variables; until drones run the majority of logistics routes, we will utilize vehicles that must navigate mountains, lakes, cities, and circuitous roads. And don’t forget border crossings, tolls, and weather! Even sophisticated design tools sometimes rely on a circuity factor to serve as a proxy for road distance. But the real world is not that clean.

Example 2: A warehouse in Milwaukee will look like it is perfectly situated between a customer in Grand Rapids and another one west of Madison. But the delivery to Grand Rapids must go south of Lake Michigan and navigate through Chicago. The customer west of Madison is right down a major highway and — barring a Badgers game — traffic is usually civilized and quick through that city. Again, center of gravity will be off by roughly 2X in this example.

And Problem #3 →Inbound transportation will skew the optimum location in the direction of the suppliers. Granted, outbound transportation is costlier per mile than inbound, but inbound is still a determining factor in most cases. And if the inbounds are from distinct markets and directions, the optimum solution will draw the best site location towards those inbound directions.

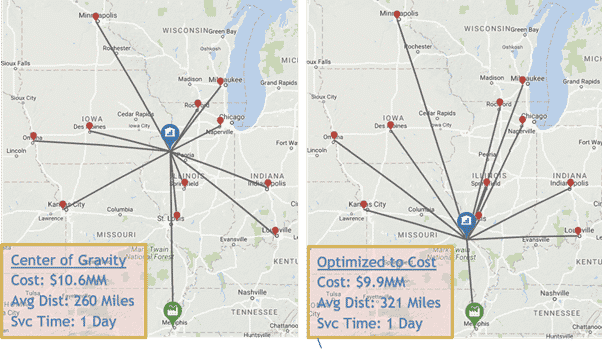

Example 3: In this case, a set of customers in the Midwest are supplied by a plant out of Memphis. The center of gravity analysis would suggest a site north and west of Peoria (in a corn field), but the optimum location is just south of St. Louis. True, the service distance for these customers might become a factor in many cases. However, we are showing that the center of gravity study in this case would leave over 6% cost savings on the table.

Is It Really That Bad to Use Center of Gravity?

Actually, yes — center of gravity analyses are easy and understandable (as well as quick and cheap). They have the appearance of being good enough and are certainly faster and more economical than the traditional approach of doing a detailed network model. The inherent danger, as our examples show, is that these studies often place the center of gravity far from the optimum location. It is the rare logistics manager who is willing to leave 5–6% savings on the table.

What Is Better Than Doing Center of Gravity? (without a big fuss)

The short answer is to use Logility’s network optimization gaming simulation engine to model your network. It is fast, powerful, and mitigates the three deficiencies listed above. Logility’s solution uses rapid prototyping technology and market data to give an accurate picture of transit times and costs. It employs a whole new paradigm for answering site location questions better and faster than center of gravity studies:

- Transportation rates and markets are used to reflect actual costs

- Drive times and real distances are made very simple with our cloud-based platform

- Inbound transportation is modeled easily and visually using the visual gaming engine.

We live in the era of internet-based tools, big data, and powerful computing. We should leverage these for our logistics decision-making. Each month that passes without a decision is one month of annualized savings lost.

Logility helps organizations sense and respond to changing market dynamics and more profitably manage their global businesses and become resilient, sustainable enterprises. It’s time for a digital, sustainable supply chain. Reach out to our specialists today to discuss our supply chain solutions.

Written by

Steve Johanson

SVP Industry Principal

Short bio

Steve Johanson is the SVP Industry Principal for network optimization at Logility, where he draws on 25 years of helping clients optimize their supply chains. Steve works with the Logility team to bring new and innovative solutions to the greater supply chain community and to help the client base build skills and knowledge to sustain competitive advantage.