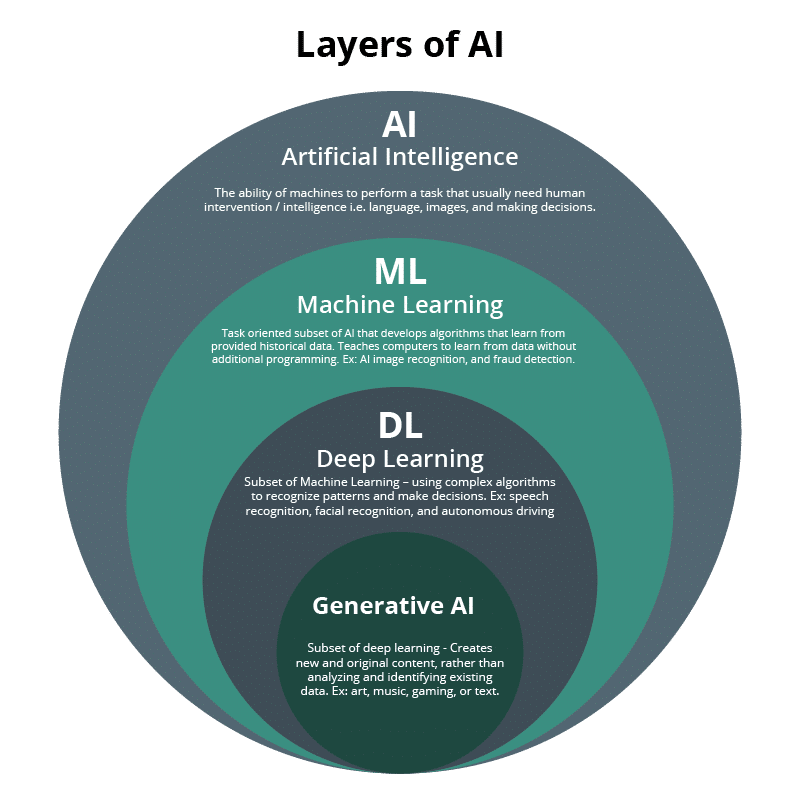

AI has captured widespread fascination, igniting imaginations across various sectors. From generative AI for supply chain to AI-assisted development and copilots, the potential of these advancements has gained significant attention when it comes to revolutionizing work efficiency, streamlining decision-making processes, and elevating business productivity.

Business leaders are particularly interested in the potential improvements AI presents, according to a BCG survey. Over half (54%) of surveyed executives anticipate AI to yield cost savings in 2024. Among them, half foresee a substantial increase of 10% or more through productivity gains across their operations, customer service, and IT areas.

Supply chain operations is another business area where further cost savings can be found. Incorporating AI and, generative AI for supply chain, to analyze demand trends, supplier capacity, resource utilization, and production performance can uncover predictive patterns and prescriptive insights to optimize strategies – ensuring a seamless flow of product and revenue.

A gradual, behind-the-scenes transformation

Contrary to popular belief, the presence of AI in everyday experiences is not as recent as one might think. Instead, it has quietly evolved behind the scenes as our reliance on technology has grown.

Take, for example, autonomous driving – a field that witnessed an early innovation in Mitsubishi Motors’ alert system back in the early 1990s. This system flashed a message on the dashboard if another vehicle approached too closely from the front or rear, allowing the driver to preemptively address the situation and prevent potential accidents.

Although Mitsubishi’s innovation was a relatively simple concept, the evolution of AI-driven alerts over the past three decades has been profound. Today, individuals instinctively rely on numerous AI-assisted tools in their vehicles, from turn-by-turn navigation instructions and automated steering to risk assessment through driver monitoring systems.

Supply chain organizations have mirrored a similar AI journey for a long time. Managers, planners, and suppliers have become accustomed to responding to alerts and signals. And as AI capabilities and generative AI for supply chains continue to advance, so do the advantages, like:

- Faster availability of insights to executive leadership and greater transparency for supply chain planners and all other business functions

- Ability to leverage multiple forecasting methods simultaneously, enhancing accuracy and adaptability, with less reliance on historical data and one algorithm

- Precise sequencing of promotions, product introductions, and demand sensing, leading to a more flexible process

Despite spending less time on number crunching and product prioritization, supply chain teams now better understand the health of their product lines and the company’s overall profitability. Also, their supply network is more interconnected, leading to financial decisions based on real-time economic indicators, vendor performance, and market expectations.

Advancing strategies with intelligence, flexibility, and speed

As we assess the current state of AI in supply chains, it’s evident that the technology has been deeply ingrained in our processes and tools for a while now.

Data-driven decision-making involves leveraging vast amounts of data to gain insights into various aspects of the supply chain, from market trends to competitor behavior. By integrating an AI-first approach into the data ingestion process, organizations can build a comprehensive and dynamic foundation for generating actionable insights and driving informed decision-making. This foundation is critical to laying a framework for ensuring the intelligence generated is trusted by users.

Anomaly detection is another critical aspect of the AI-first model. It enables organizations to identify deviations from expected patterns and proactively address potential issues. Through techniques such as synthetic data generation and data mining, AI can uncover hidden insights and anticipate future trends, enhancing the overall resilience and agility of supply chain operations.

Once the foundation is set, we can leverage an ensemble forecasting and AI-first approach that proves a shift in demand planning, moving from traditional sequential processes to a more holistic and integrated approach. By combining multiple forecasting methods and leveraging AI algorithms, organizations can generate more accurate forecasts in real time, improving overall forecast accuracy.

The possibilities presented by AI in supply chain management are truly endless. From improving forecast accuracy to leveraging a wide range of demand drivers, AI has the potential to revolutionize how organizations anticipate and respond to market dynamics. Supply chain professionals can deepen business-wide understanding of their operations and make informed decisions by harnessing the power of data and AI-driven insights.

Tomorrow’s edge delivered today with GenAI capabilities

Looking ahead, the next phase of AI promises to be remarkably transformative for supply chains. But what excites us about the present era is not just the speed at which technology is evolving but also the breadth of its application. Generative AI for supply chain in particular, has opened up new possibilities, allowing us to explore innovative approaches to problem-solving and decision-making.

Innovation surrounding GenAI is democratizing intelligence, fostering broader and more meaningful engagement in decision-making processes. This empowerment enables companies to effectively navigate inflection points and optimize strategies for success. The emphasis has shifted away from simply restoring supply chains to their “normal” state; instead, there’s a focus on surpassing this norm through AI-driven visibility and responsiveness.

With the latest updates in the DemandAI+ solution, Logility is seizing this moment to equip companies with tools to tackle dynamic market conditions. This ensures supply chain organizations can respond effectively to sudden changes in demand, swiftly deliver decision-quality data, and retain valuable demand knowledge for future planners.

By replacing traditional methodologies and aligning with the pace of the market, the GenAI+ capabilities within the DemandAI+ solution provide critical advantages to supply chain organizations worldwide. These benefits have delivered:

- 70% savings of weekly planning time

- 15-30% reduction in forecast error

- 16-32% lower inventory costs

The best part of using the out-of-the-box brilliance of GenAI is the ability to unleash the power of AI without the learning curve.

Every new AI innovation from Logility is designed to let supply chain organizations become superheroes of their company. They can engage in conversations with the rest of the business and their supplier network in ways everyone can understand – effortlessly and with maximum impact. Meanwhile, every supply chain secret is safeguarded with top-tier security capabilities.

No jargon, no barriers – just crystal-clear insight

Integrating AI into supply chain operations marks a significant shift to a more efficient, adaptable future. As technology continues to advance rapidly, AI is poised to become a permanent fixture driving innovation and reshaping industry norms.

By embracing AI as a strategic ally, companies can position themselves at the forefront of industry advancement – reinventing themselves and their industries in ways that pave the way to the next level of success.

The New Era of AI-Powered Supply Chain Decisions

How can your business benefit from an AI-first approach to supply chain planning? Watch this webinar recording to learn how.

Free Webinar

Written by

Scott Tillman

SVP, Innovation

Short bio

With over 25 years of experience, Scott Tillman drives supply chain innovation at Logility. His experience includes business process reengineering of supply chain operations and ERP implementations for Fortune 500 companies in the high-tech, process manufacturing, retail, and healthcare industries. His leadership roles within software companies range from product management to engineering, focusing on the development of supply chain solutions specific to inventory replenishment, demand forecasting, and distribution management.