Younger generations who have grown up with the threat of global warming, holes in the ozone layer, greenhouse gasses, etc. have a much different focus on what it means to be eco-friendly. The topic of sustainability and being eco-friendly is discussed in K-12 education on a regular basis. In fact, it is not unusual for kids to come home and ask their parents what they are doing that benefits the environment. I would venture to say that, like myself, most parents find it difficult to respond with a good answer to that question. So, I started thinking about how supply chain management can impact the environment and concluded that supply chain managers are Green Superheroes.

Almost every supply chain improvement made to reduce costs has a beneficial side effect that contributes to the Greening the supply chain. Most improvements are made through more effective planning or more efficient operations. For example:

- Optimizing a distribution network not only reduces logistics costs but, in most cases, reduces carbon emissions through fewer transportation miles and/or less inventory holding costs.

- Higher forecast accuracy supporting a mature S&OP process allows a company to hold less inventory, run more efficient plants, and improve transportation efficiency. Better supply chain planning saves money but also reduces greenhouse gases and decreases your company’s carbon footprint.

- Scenario planning enables a company to find the most efficient and effective solution to unexpected events, ensuring a high-level of customer service while minimizing costs. Often the lowest cost scenario is also the best one from a Green standpoint.

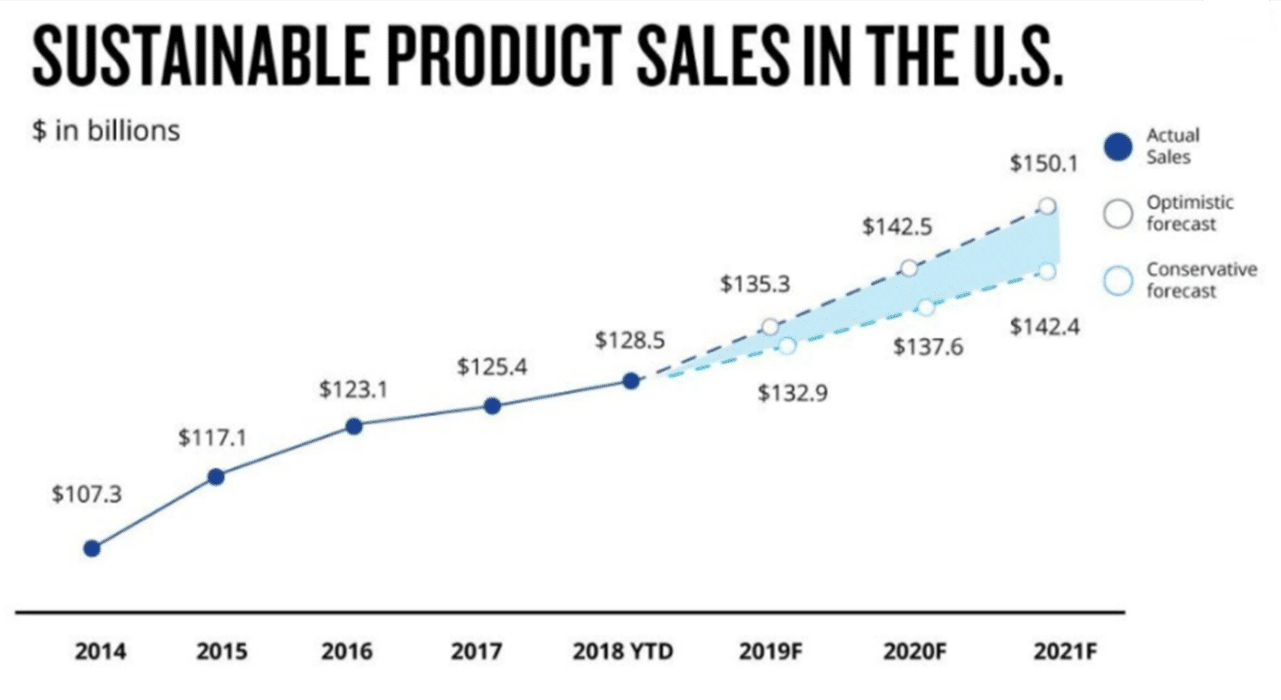

Following and supporting “Green Supply Chain” practices is important to a growing portion of the population and can positively affect brand awareness and market share. There is increasing evidence that in addition to a positive reputation, brands that follow and claim eco-friendly policies can charge more for their products. The results from another study reported that over 60% of Gen Z and Millennial shoppers prefer to buy from sustainable brands. Further, 50%+ of these younger shoppers are willing to spend up to 10% more on sustainable products.

Source: Nielsen Product Insider, 10/20/2018

As a supply chain manager, how do you start your journey to becoming a Green Superhero?

Unfortunately, an industry-accepted definition of a “Green Supply Chain” does not exist. So how does one build one? Is it enough to be eco-friendly in some processes, like transportation or manufacturing, to qualify your company as being Green? What about warehousing, inventory management and the efficient maintenance of your capital equipment? Must every supply chain function be eco-friendly, or can you focus on some areas of the supply chain and still be considered Green? There is no easy answer, however most experts agree that building a Green Supply Chain is like implementing other Supply Chain Improvement Projects: It’s a journey, Not a destination.

According to an article published in the MIT Sloan Management Review, for most companies, becoming sustainable involves a conscious and continuing effort to build long-term value for shareholders. The article listed characteristics of sustainability leaders:

1. They take a long-term view when making decisions.

2. They are willing to take measured risks in pursuit of sustainability.

3. They learn from the outside and are far more likely to encourage their employees to assimilate knowledge from sources external to their company.

4. They encourage their supply chains to adopt sustainable strategies.

5. They incorporate sustainability metrics into the capital budgeting process, develop solid valuation processes that take externalities into account, set clear targets for sustainability objectives, and establish targeted programs linking the objectives to business results.

A good place to start the journey of Greening your supply chain is to focus on initiatives that will improve operational efficiencies. Unfortunately, many efficiency improvement projects have a functional focus and just lead to inefficiencies in other areas of the supply chain. For example, maximizing plant efficiencies often leads to larger inventory holdings and less efficient distribution. Your ability to improve integrated supply chain efficiencies is greatly enhanced if you utilize a Supply Chain Digital Planning Platform like Logility. An advanced planning platform provides one place to visualize and analyze product, service, costs and sustainability information to enable intelligent tradeoffs.

Supply chain practitioners should measure and publicize not only the economic but also the ecological impact of supply chain improvements. Next time someone asks you what you have done to improve the environment, put on your Green Cape and tell them about your Green supply chain improvement projects.