It’s called the house of quality because the outline and levels of the matrix resemble a house. The foundation of the house of quality is the belief that products/services should be designed to reflect customers’ desires and tastes. To achieve that, the entire company must work together starting at product conception. The house of quality is a conceptual map that facilitates inter-functional planning and communications. In a way Integrated Business Planning (IBP) also is a framework for inter-functional planning and communications and is used by companies to ensure alignment and synchronization of demand and supply for products and services. I thought it would be interesting to discuss the components of IBP in a “House of Planning” framework.

The Entire House: Integrated Business Planning

Thousands of companies of all size and types have reduced costs, improved service, and gained competitive advantage through Sales and Operations Planning (S&OP) initiatives. However, many companies have plateaued in their S&OP process maturity and are looking to take planning to the next level – which may very well be Integrated Business Planning (IBP).

IBP is a comprehensive process that blends strategic business planning, financial planning and tactical Sales & Operations Planning. IBP synchronizes higher-level and operational supply chain planning by combining data from sales, marketing, production, procurement, transportation and finance. It removes organizational and technology barriers, aligning and synchronizing plans to provide one powerful decision center for all stakeholders.

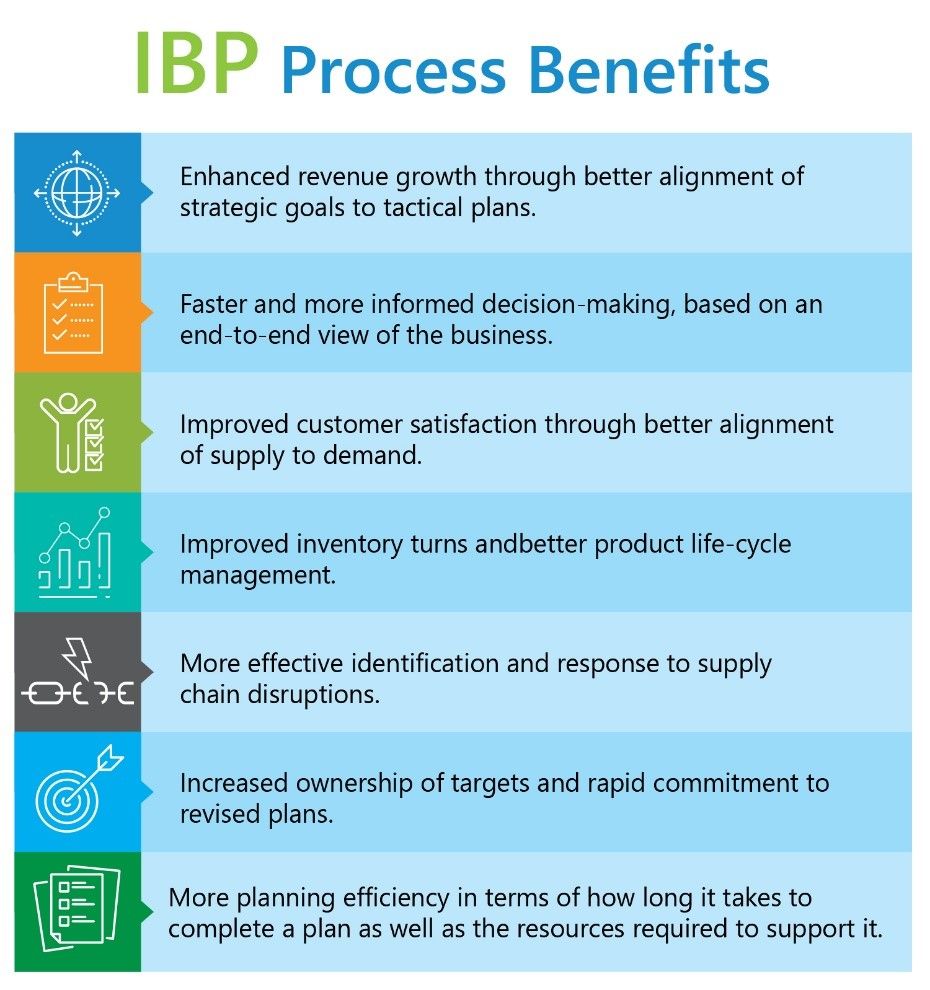

The benefits of IBP go beyond those of S&OP in several important ways. Fundamentally, IBP simplifies complex, cumbersome, and disconnected tasks within a single integrated planning process. When supported by a collaborative platform that encompasses all relevant data, IBP streamlines and unites planning activity across the business, from demand, inventory and supply to manufacturing, financial planning and strategic planning.

Attic: Strategic Planning

The purpose of long-range planning is to understand what market and other conditions may exist down the road, identify areas of opportunity, and anticipate what competitors may do over an extended time horizon.

Unfortunately, most strategic planning processes are very manual and almost never take the results of lower planning processes into consideration, producing a lack of realism that often makes the strategic plan unattainable. IBP unites multiple disciplines and multiple process steps to develop an optimal business strategy, managing risk and developing mitigation plans, and seeking out business opportunities.

Top Floor (Bedrooms): Financial Planning

Customers expect the same level of service no matter what sales channel they engage, division they are dealing with or where they reside. Companies cannot afford to experience latency in supply chain planning information due to system disconnects.

Integrating S&OP, financial planning and strategic planning into one comprehensive Integrated Business Planning (IBP) continuum revolutionizes the level of insight available to management teams and ensures high customer service while maximizing company performance.

Main Floor (Kitchen/Living Room/Dining Room): S&OP

Integrating S&OP and strategic planning into one comprehensive Integrated Business Planning (IBP) continuum revolutionizes the level of insight available to management teams.

Global visibility, smart real-time reactions to exception conditions and forward-looking analytics drive thoughtful, proactive decisions that minimize future supply-chain risk while maximizing business effectiveness.

Basement (Recreation Room, Tool Shop, etc.): Supply Chain Planning System of Record

Most companies today are too busy manually manipulating and aligning data, reacting to the latest disruption, and adjusting supply to try to meet constantly changing customer demand to get much beyond a basic monthly demand/supply planning process.

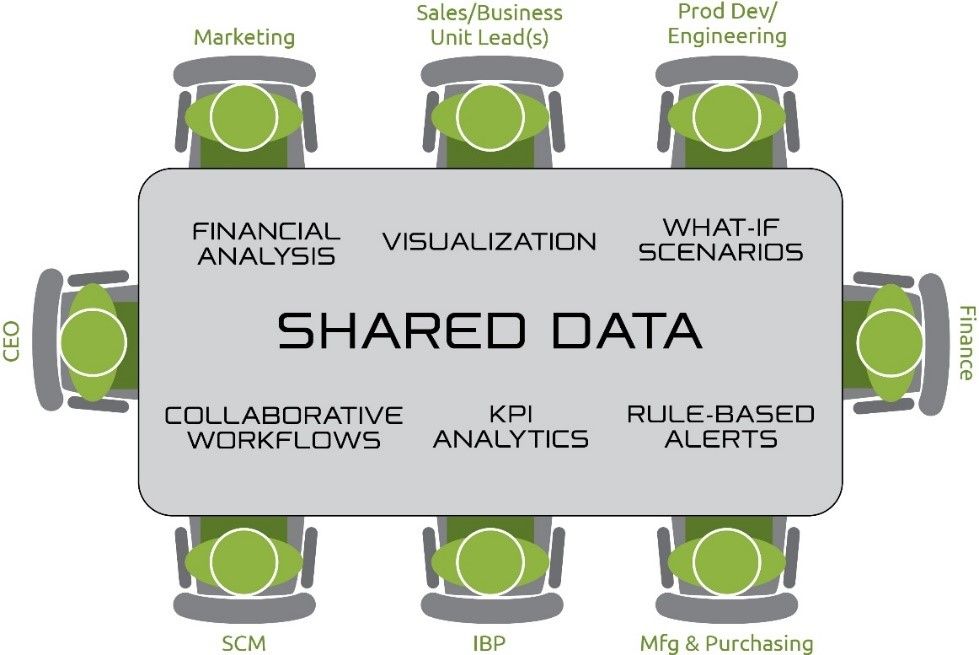

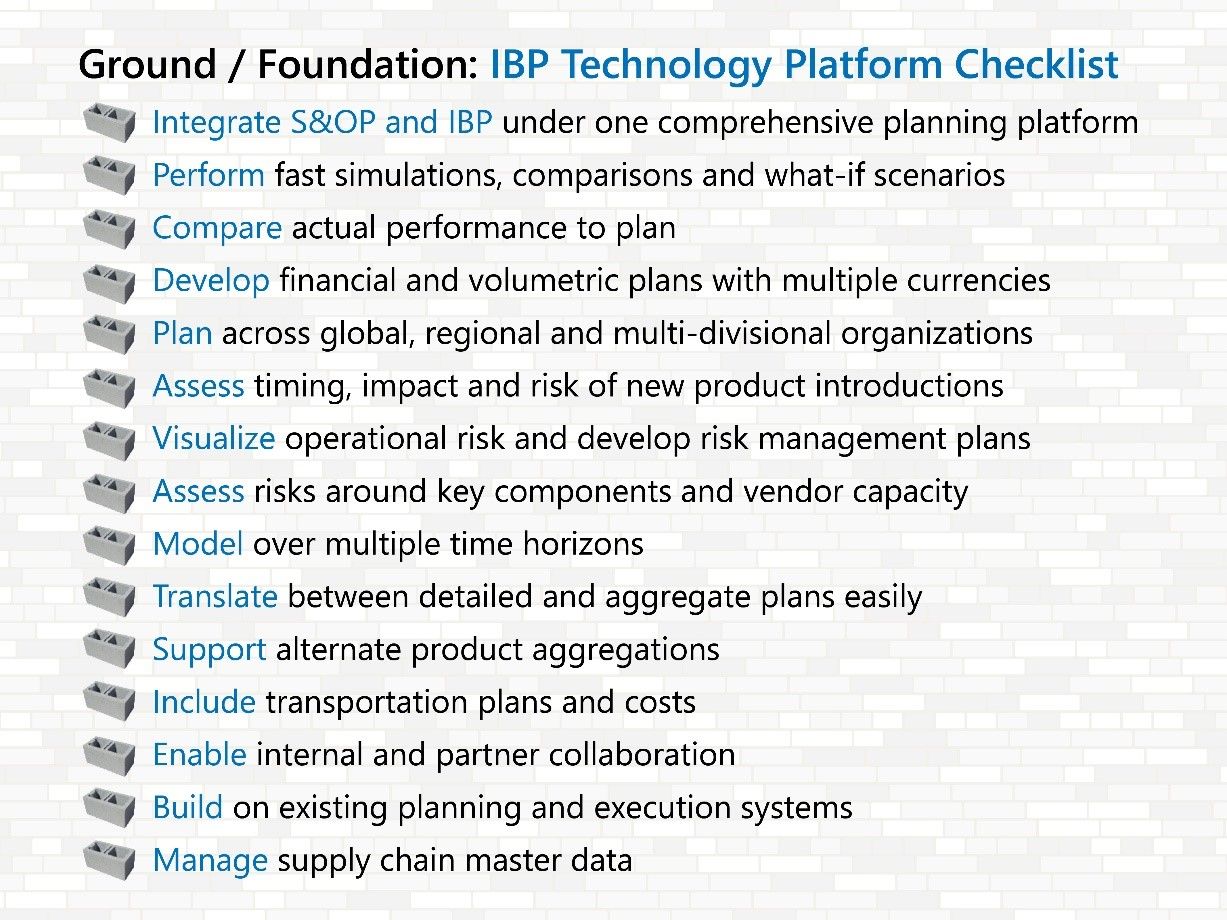

Synchronizing and aligning all relevant business planning data in a common platform allows your valuable planning resources to focus on analyzing data to develop recommendations and take actions that lead to added business value. Financial and volumetric data is connected to bring new understanding through advanced numerical and visual analytics. Analyses are conducted in the timeframes and units most appropriate to identify opportunities and minimize risks. Sets of alternatives are developed through “what-if” scenario analysis, simulations, and other advanced tools to develop the optimal response to changing supply chain information.

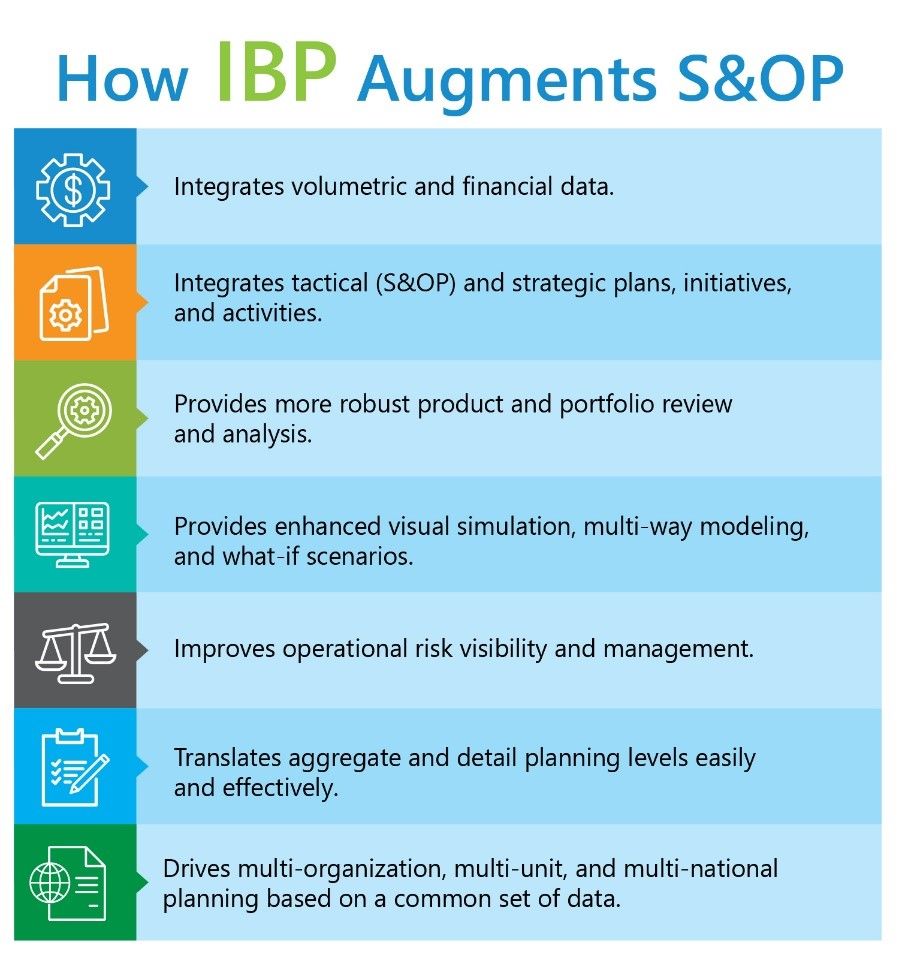

Not only does Integrated Business Planning integrate volumetric and financial data, it also links tactical and strategic plans, allowing planners to translate between aggregate and detail planning levels easily and effectively. Companies that adopt an IBP process can perform robust product and portfolio reviews as well as enhanced modeling, simulation, and what-if scenarios. IBP encompasses the broad scope of multi-organization, multi-unit, and multi-national planning based on a common set of data, while also improving operational risk visibility and mitigation capabilities. The IBP process helps extended management teams align and synchronize planning processes in one highly visible and accessible shared environment that spans planning time horizons as far as a decade or more into the future. In those companies that have embraced the House of Quality, maybe explaining IBP in a House of Planning metaphor will accelerate adoption.