Today, many companies run separate processes for long-, medium- and short-term business planning. These individual plans are built from different data sets, based on varying business assumptions, displayed in different units and across different horizons and rely on different systems. It is not surprising that these separate planning processes produce very different results and generate very different recommendations. Trying to integrate these different plans after the fact is next to impossible. Details will be lost or miscommunicated in the data translation efforts leading to strategic plans that lack operational reality and operational plans that lack strategic focus.

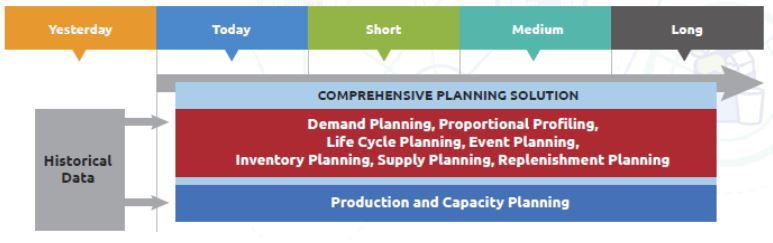

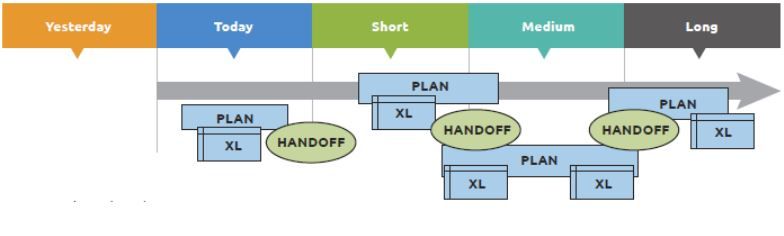

Instead, efforts should be focused on generating a single, integrated business planning process supported by a single platform that enables intelligent multi-horizon planning. A platform approach drives closer collaboration between planning teams, ensures consistency from one planning horizon to the next and allows the team to adjust plans confidently and quickly as the market shifts. Handovers are seamless and everyone receives reliable answers sooner. Accurate forecasts and capacity plans are developed at the appropriate aggregation level and time horizon. It’s a win-win for the everyone involved.

Where once disconnected planners had to scramble to solve issues that were identified too late to effectively mitigate the situation, an integrated platform provides instant alerts to deviations from the plan. Lag time and opportunities for miscommunication and distrust decrease. The tendency to “order too much” also decreases, which helps to eliminate the creation of excess inventory buffers. Crucial long-term planning can be executed earlier with confidence, thus winning the race with competitors vying for capacity and resources at the same suppliers.

Consolidating the phased planning process improves communication, trust and responsiveness while also delivering a strategic advantage in the form of faster, more insightful “what-if” scenario analyses. This is what every supply chain planner wishes for: better analysis capabilities to solve problems before they happen, freeing up time to add real value to their company’s success.

Could your company benefit from an integrated approach to business planning over multiple time horizons and a comprehensive planning platform that supports short-, medium-, and long-range planning? If so, Logility can help.