Climbing the Ladder of Analytics Value

Climbing the Ladder of Analytics Value

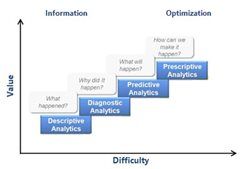

Amid the general buzz in the supply chain planning field regarding optimization solutions and algorithmic planning, a diagram of value vs. difficulty lays out four stages of analytics by their difficulty and potential value. In the quest to do more with less, drive costs out of the supply chain, and provide higher levels of customer service, optimization and algorithmic planning are subject to a company’s analytics abilities and level of sophistication.

Let’s explore each of these levels (Descriptive, Diagnostic, Predictive, and Prescriptive) a bit and highlight the processes and solutions you might want to investigate to climb the ladder of analytics value.

The Descriptive Analytics level is easiest to achieve. Just about every supply chain planning organization has the ability to determine “what happened.” It’s often achieved through dashboards, reports and event management, using data analysis tools like clustering, pattern-based analysis, visualization and reporting. Most systems provide these types of descriptive analytic capabilities, however knowing “what happened” is often inadequate to make adjustments that improve future performance.

Diagnostic Analytics help to answer the question “why did it happen” (root cause analysis is a classic example of diagnostic analytics). Often supply chain performance and visualization can also help to determine why something happened. Diagnostic analytics often involves analyzing data using simulation, “what-if” analysis, and queries. Determining why something took place is a good first step in making improvements but still falls short in getting out in front of new problems. Basically you are still “firefighting,” reacting to events in the supply chain.

Predictive Analytics help companies get out in front of events and disruptions to enable a proactive approach (“what will, or could, happen”). Statistical forecasting is a great example of Predictive Analytics, as well as the application of risk management and mitigation through simulation and “what-if” scenario analysis. Some companies use network and production simulation to predict and plan for changes in the supply chain. Machine learning is all about adopting technology that can learn from past events and predict what might happen in the future. Many companies invest in Sales & Operations Planning to try to determine what will or might happen. Knowing what will, or could, happen helps proactively design the business to be proactive in approaching those events. Britain’s exit from the European Union, known as Brexit, is an example of having advanced knowledge of a major potential supply chain disruption. However, just knowing Brexit is going to occur doesnt necessarily help in determining the best course of action for your supply chain and company (read more in the post, Brexit: Supply Chain Risk or Opportunity?). You need the ability to evaluate multiple scenarios to predict the optimal plan for your business.

Prescriptive Analytics is the highest stage of analytics. It answers the ultimate question, “what should I do?” Determining the best path forward generally involves some form of deterministic or stochastic optimization. Deterministic optimization focuses on finding an optimal solution to a problem while meeting some predefined goals. Linear programming, mixed-integer linear programming, and non-linear programming models are all types of deterministic optimization. Commonly deployed examples of supply chain planning optimization solutions include inventory optimization, supply optimization, factory finite scheduling, network optimization, and transportation optimization. Optimization answers the question “what should I do” to maximize profits, minimize costs, and meet customer requirements. Optimization can also be used to automatically respond based on predetermined criteria, allowing the supply chain team to manage by exception and do more with less.

The ultimate goal for any company should be to embrace Prescriptive Analytics. As with many processes and technologies, it is best to build a strong foundation before trying to add higher level functionality.

Where is your company on the analytics ladder of value?