Even the most seasoned demand planners have struggled against unprecedented challenges in recent years. An increasingly accessible global supply chain, massive increases in the availability of consumer data, and other continued complications have brought rapid change to the process of delivering products to consumers.

To meet the changing demands and continue to thrive, organizations need to find a way to align themselves with the permanent changes in the world and acquire the capability to translate them into insights. Unlocking the human planners’ full potential and continuing to provide the best service for companies’ users is only possible by putting these planners in control of the latest evolutions in AI and machine learning (ML).

Opening the Black Box for Demand Planners

The limited capabilities of the current demand planning, forecasting tools & processes unnecessarily restrict planners. Without adequate technical support, they do not have the bandwidth to effectively apply their knowledge and intuition to meet today’s supply chain demands. Moreover, when the results are black box and non-explainable, they become difficult to be executed given within the ownership and accountabilities of the responsibilities of different parts of the organization.

Meanwhile, the latest evolutions in AI and ML have unlocked previously unheard-of data-processing and forecasting capabilities. However, without proper application and human guidance, there is no way to utilize these insights within an organization effectively.

The solution lies within the union of experienced, adaptable demand planners to user-friendly AI/ML systems to approach demand planning. This technological revolution will allow organizations to push beyond static and inflexible forecasting processes that rely too heavily on a now irrelevant past, and remove the need for implementation by handing the planners to power and capability to adjust data, processes and algorithms to align with the changes at hand.

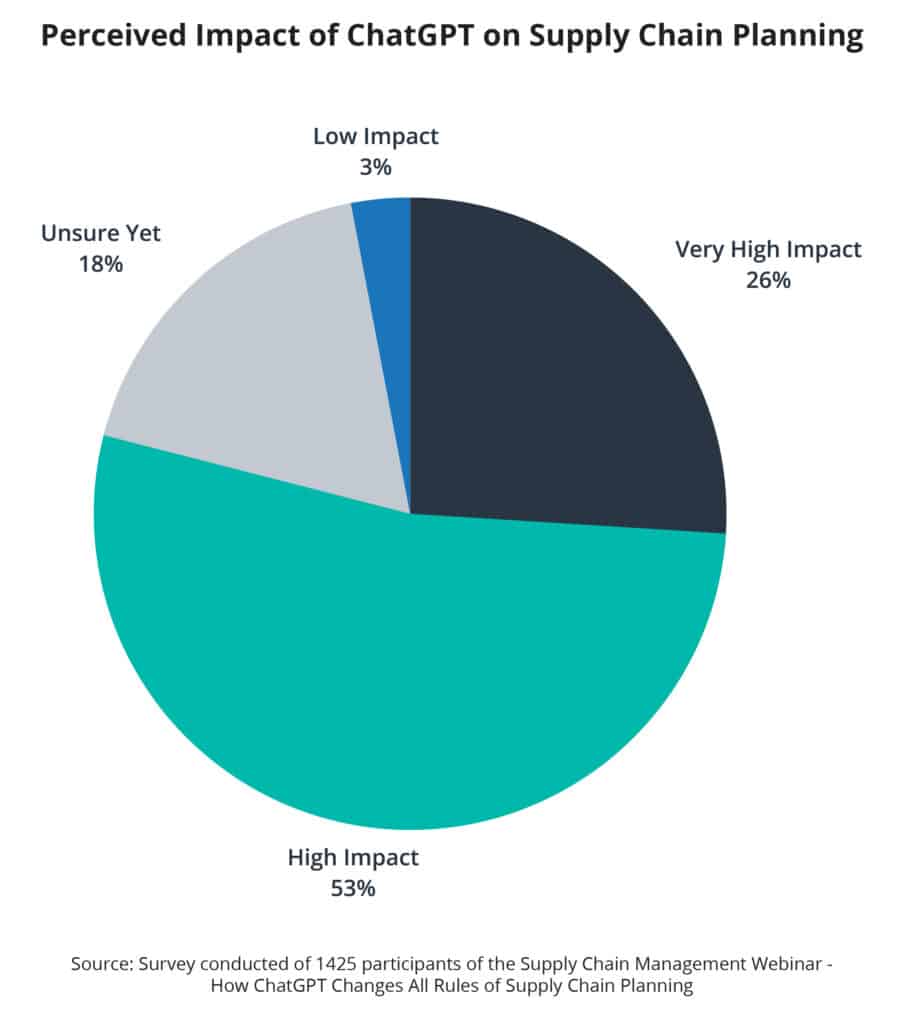

Realizing Value with ChatGPT and AI-First Forecasting

Two-part series: this webinar provides valuable insights into the potential of AI and ChatGPT and the substantial savings & operational excellence companies have seen.

Free Webinar