There has been a collective sense that 2021 was going to be the pivot, the year in which we would turn our backs on the pandemic and look forward to a better future. We now know that there’s no sense waiting for COVID-19 to take a bow and exit gracefully. In the spirit of setting some resolutions for 2022, here are five priorities to consider in a climate that continues to disrupt supply chains globally.

Traceability

Supply chain transparency and traceability is a must-have for organizations that want visibility into every level of their multi-tier supply network to share critical information with stakeholders.

A 2021 McKinsey report suggests that COVID has put supply chain risk on everyone’s radar. Most respondents (95%) say they have formal supply chain risk management processes, and 59% of companies say they have implemented new supply chain risk management initiatives in the past year.

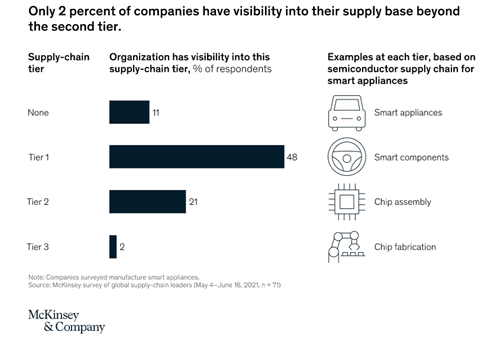

That’s all well and good, but the report goes on to say that “significant blind spots remain.” Indeed, about half the survey respondents claimed to have a good understanding of their tier 1 suppliers, but only 2% could say the same about tier 3+ suppliers. It’s not surprising that this lack of visibility leads to firefighting, but it also undermines sustainability and compliance claims.

To maintain brand integrity and credibility, comply with new and expanding legislation in the U.S. and abroad, and satisfy consumer expectations, a transparent supply chain supported by the necessary traceability technology is no longer just a nice-to-have.

Compliance

We often encounter compliance in the context of the rapid ‘greening’ of consumer sentiment or the increasingly aggressive regulatory climate. Companies want to attract consumers who value sustainability while satisfying rule-makers large and small.

Public Sector Pressure

In December 2020, U.S. Customs and Border Protection (CBP) issued a Withhold Release Order (WRO) on cotton products sourced from China and south-east Asia. It was a stark reminder to businesses of the need to take charge of their supply chains.

And it was only the beginning. President Biden signed the Uyghur Forced Labor Prevention Act into law on December 23, 2021. The law bans the import of any goods produced in China’s Xinjiang Uyghur Autonomous Region (XUAR), and it goes into effect on June 21, 2022. Without a verifiable chain of custody proving products or materials are in no way connected to the XUAR, items detained by CBP will need to be re-routed to another country, abandoned, or destroyed.

The Consumer Voice

Granted, consumer sentiment is notoriously volatile, but research consistently shows consumers will use their purchasing power to advocate for sustainability. The July 2021 Global Sustainability Study, conducted by Simon-Kucher & Partners, involved more than 10,000 people across 17 countries. One key finding: 85% of respondents indicated that they have shifted their purchase behavior toward sustainable products over the past five years. As mentioned earlier, most companies do not have the capability to show evidence that each tier of their supply chain meets the standards customers increasingly expect.

Here we see the interplay among our five supply chain goals for 2022. Ironclad compliance requires comprehensive traceability, but there’s more to it. There’s value in gathering information on your suppliers’ progress toward compliance and sustainability. But there’s much more power in integrating that information into your real-time planning processes.

Integrated Business Planning

Fully distilled, integrated business planning (IBP) is all about consistent, rigorous communication. It’s a series of coordinated processes for driving desired business outcomes into financial and operational resource requirements. The outcomes can be expressed in terms of balanced achievement across the following:

- Revenue and demand

- Service levels

- Inventory levels

- Profits and margins

- Cash flow

Unfortunately, fragmented planning methods and static reporting prevail, strategic planning is based on outdated data and often unrealistic supply chain capabilities, and tactical planning is a constant firefight with no regard for strategic objectives.

IBP is a unified planning and decision support system that covers strategic and tactical horizons in one solution. According to industry research comparing the performance of companies that follow an IBP approach versus those that don’t, IBP users are faster to react to unexpected disruptions in the supply chain, better able to align supply and demand over the entire horizon, more effective at collaborative planning, and able to reserve capacity with suppliers earlier and more efficiently.

The advantages of aligned, collaborative planning across the enterprise cannot be underestimated in an age when resilience and preparedness is being heavily tested. And today’s customers are looking for large, stable companies they can continue to depend on, irrespective of disruptions.

Acceleration through Automation

We often think of supply chain automation as the way to reduce cycle times and eliminate human error. The next frontier is already here: artificial intelligence (AI) and machine learning (ML) automate the decision-making process, not just decisions already made, without any distortion from human bias. A simple example is the ability to detect shortages and quickly simulate, evaluate and implement alternative replenishment scenarios.

AI and ML technology is already driving dead cost out of our supply chains by predicting and managing equipment maintenance schedules, improving quality and safety in the food and beverage industry, and identifying potential disruptions before they reach crisis stage. Research shows AI’s positive impact on profitability is growing. In a 2021 McKinsey study, the portion of respondents reporting at least 5% of earnings before interest and taxes attributable to AI jumped year over year from 22% to 27%.

The Logility® Digital Supply Chain Platform’s AI engine continuously senses, analyzes and updates supply chain planning parameters in real time to help ensure peak operational performance. AI and ML algorithms take care of extracting valuable information from ever-increasing volumes of structured and unstructured data, at the same time freeing up essential resources.

Win the Talent War

In short, there are too many supply chain management job openings chasing too few candidates. A 2017 DHL survey claimed that the talent shortage was severe five years ago: six openings for every candidate. On LinkedIn, the number of supply chain management openings has nearly doubled in the past two years, irrespective of the fact that more than 150 schools in the U.S. offer associate’s or bachelor’s degrees in supply chain management. A snapshot of LinkedIn in 2019 showed 88,000 jobs available; by early 2022, that number had increased to close to 153,000.

Agree on the Ideal Candidate

Keep in mind it’s a candidate’s abilities that matter, not the tech they know today. The tools always change; the ability to learn what’s next is more important than knowing how to use today’s tools. As Karen Smith, vice president of Global Supply Chain Operations at Kontoor Brands says, “We try to find candidates who are tech savvy, have used some technology solutions and have an aptitude to learn to use others. Candidates must be comfortable asking “why” questions and have strong decision-making and communication skills. Also, no one who has spent time, effort and money on a four- or six-year supply chain degree wants to join an organization that is still being run by Excel. Not that Excel is a bad tool, but spending time moving data around from one spreadsheet to another is not a good use of skillsets.”

Play Offense

Some companies view attracting talent as “set the bait and wait.” Better to go on the offensive, says Sean Willems, PhD, Haslam Chair of Supply Chain Analytics at the University of Tennessee. “Partner with the closest university to you. Sponsor a case competition. Coach a team. Teach a class. Send your smart people in, let them identify who the best students are for your company, and make them offers before everyone else. The department head at your local university will thank you.”

Empower Strategic Outcomes and Resilient Planning with Logility

Unpredictable as well as predictable events will continue to challenge supply chains throughout the coming year. Building resilience takes time, money, and a top-down commitment, but the cost of doing nothing is far greater. Plan to develop comprehensive traceability that reaches the depth and breadth of your supply chain. This capability is a necessary component of your own compliance strategy, but compliance should go beyond understanding whether a supplier is meeting its commitments. Compliance data should be used as an input into capacity planning.

And speaking of planning, make this the year you unify your company’s demand and supply planning while adopting innovative technologies to automate decision-making. As for hiring, build the ideal candidate profile, seek them out, and then arm them with the opportunities and tools that will motivate them to contribute meaningfully for years to come. For more information on how Logility can help you achieve your supply chain goals for 2022, talk to us today.

More reading:

Supply Chain Traceability Ensures Supplier Transparency (logility.com)

https://www.logility.com/blog/supply-chain-compliance-requires-compliance-throughout-the-entire-supply-chain/

https://www.logility.com/blog/want-to-make-integrated-business-planning-a-success-heres-how/

https://www.logility.com/white-papers/making-the-case-for-ai-and-machine-learning/

https://www.logility.com/white-papers/attracting-keeping-supply-chain-talent/