In this Q&A, industry expert and Logility EVP and principal Mark Burstein describes the current business climate and spells out how the fashion industry should respond to increasing pressure to embrace supply chain traceability maturity.

Mark’s experience as a business strategy consultant for large global brands puts him in a unique position to provide clear vision and implementation guidance for Logility’s digital supply chain platform. Currently, Mark is engaged in strategy and initiatives surrounding traceability, sustainability and ESG performance.

Logility: Please give our readers a feel for the lay of the land in the fashion industry right now.

Mark: In short, it’s a bit chaotic, and when I say that I’m fully discounting any lingering effects from the pandemic. Big brands and their supply chains are trying to understand and react to existing regulations – for example, the Uyghur Forced Labor Prevention Act (UFLPA) was signed into law in 2021, and is now well into the enforcement phase.

You can ask Uniqlo about that – last January they had a shipment of men’s cotton shirts seized by Customs in Los Angeles. Uniqlo released a statement that said in part there was no evidence of forced labor in their supply chain, but that’s not good enough. The UFLPA is built on a “rebuttal presumption” that says you are guilty until proven innocent.

Meanwhile, new regulations are on the horizon. An example is New York’s Fashion Act. It probably won’t see legislative action again until 2023, but it’s not going away. California and the federal government want to join the party, so now looming out there we have the Fabric Act, introduced in the U.S. Senate, which would increase garment workers’ wages and hold brands accountable if they work with factories that pay less than the federal minimum wage. California already passed the Garment Worker Protection Act, requiring hourly wages for garment workers, and will penalize both manufacturers and brands for illegal pay practices.

More sweeping in scope is legislation like the European Climate Law, which codifies the goal stated in the European Green Deal for Europe’s economy to become climate-neutral by 2050. It includes an ambitious milestone: reduction of net greenhouse gas emissions by at least 55% by 2030 compared to 1990 levels.

We’ve reached the point where brands and their supply partners are crying, “Stop the madness! We understand the need for rules, but give us one set that’s achievable and levels the playing field.”

Logility: You work with many large fashion companies around the world. Given the current environment, what do you see them focusing on?

Mark: Today’s focus is on transparency, speed to market and efficiency, probably in that order. But statistics released in the latest Fashion Transparency Index show that 250 of the world’s biggest brands are failing when it comes to transparency, with an overall average score of only 24% for 2022.

Logility: While coping with all these new regulations popping up, is there a big picture companies might miss?

Mark: I think there’s a big picture and a bigger picture, and companies that are careening from one regulation-specific compliance project to the next are at risk. There’s a big picture play that says brands should get ahead of rule-making by setting their sights on a comprehensive “product passport” per se. The bigger picture is all about the social contract. Are traceability and transparency investments properly aligned with overall ESG initiatives?

Logility: It seems as though many companies are convinced of the need. The burning question is: how to start?

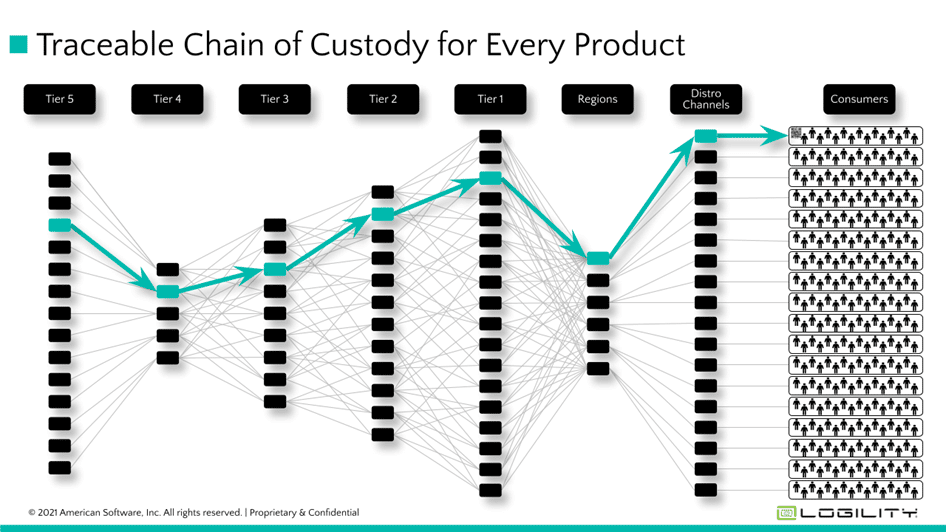

Mark: I think everyone needs to start with a goal and a framework for understanding where you are as an organization on the journey. The goal might be a complete and fully traceable chain of custody at the product level. As a framework, a low-level to high-level traceability maturity model is a safe starting point, with the lower levels looking like this:

- supplier database development and supply chain mapping – the thorough collection of names, locations, tiers and functions within the supply chain; this will support supply chain mapping, where all supplier relationships can then be identified throughout the supply network

- supply chain traceability at the item level which includes the deployment of online, configurable forms for supplier data collection and compliance document management

- the connection of goods and labor inputs as they move through the supply chain. This will provide compliance with existing legislation because you are able to produce a Proof of Admissibility certificate underpinned by a three-way match of transaction documents.

It’s important to note here that these early stages of maturity are immediate requirements for companies to be able to comply with social responsibility laws like UFLPA and cannot be circumvented for swifter maturity progression.

Logility: For a more in-depth look at traceability maturity, be sure to check out Mark’s webcast Demystifying Traceability on demand here.

Logility: We hear a lot about “digital twin” in this context. Can you elaborate?

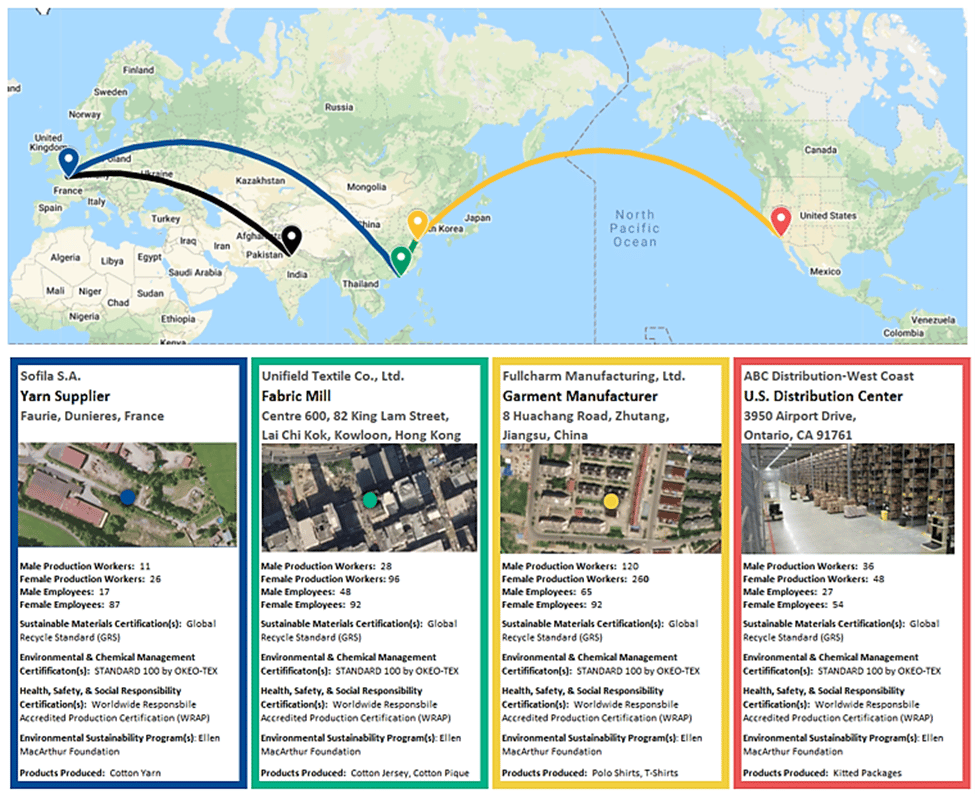

Mark: In the context of supply network mapping, it means creating a digital representation of your supplier relationships from tier 1 to tier N. Bear in mind that you’re not inventing anything new here – the transactions that take place at the outer reaches of your supply network have always existed. You just never saw them before. The digital twin creates transparency and flexibility, and is a prerequisite to achieving the higher stages of traceability maturity.

Logility: Sticking with the pragmatic for a moment, what about onboarding a new supplier?

Mark: Once online, the process is much more flexible. Today we send out Word documents and PDFs and they disappear onto someone’s hard drive. With supplier data stored in a system you can query, you’ll be able to monitor supplier compliance, issue corrective action plans and analyze the impact of alternative supply scenarios. Word to the wise – don’t underestimate the amount of work involved. It’s best to start with tier 1 and then add other suppliers who you deem high risk.

Logility: Can you talk about using existing supplier data and system integration?

Mark: Logility supports data uploads and API integrations with sustainability solutions like HIGG, but use caution here. Suppliers will likely have been approached by other customers for a variety of data, and they’ll want you to accept what they have for simplicity’s sake. Beware of gaps and irrelevant information.

Logility: What quality control and auditing practices are you seeing, if any?

Mark: We see random sampling taking place among tier 1s and tier 2s. After all, they’re carrying a lot of risk because big brands have said “we won’t pay you for product that fails admissibility.” Buying agents are often heavily involved in quality control, too.

Logility: We have to ask about cost…

Answer: Many factors play into total cost, including supplier footprint. But I can say that brands should expect some supplier push-back on any cost-sharing overtures. The good news is that the early milestones on the traceability maturity journey can be achieved inexpensively in as little as 30 days, especially when you focus on the at-risk suppliers. And ultimately you have to ask yourself: what’s the cost of doing nothing?

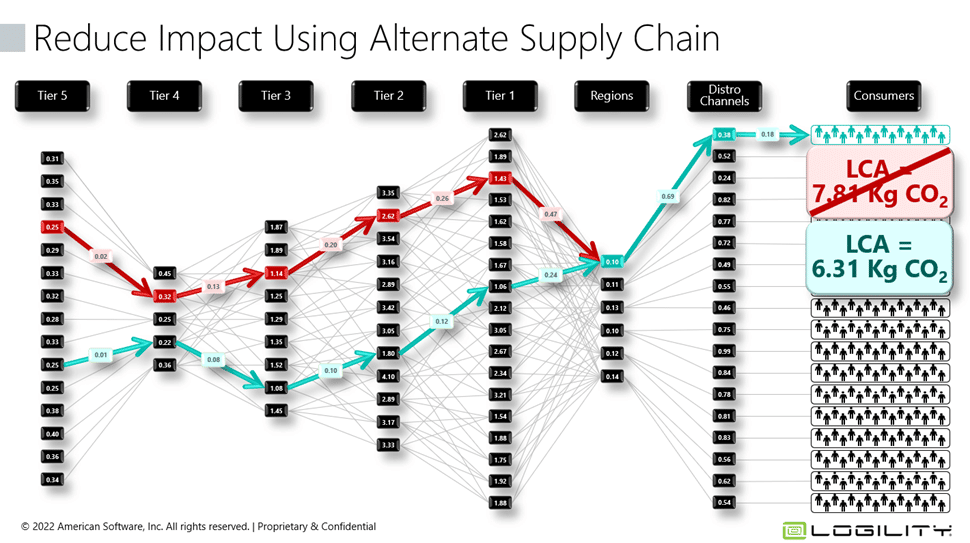

Logility: Let’s close with some vision-casting. What do higher traceability maturity stages look like?

Mark: A higher level of maturity introduces the concept of a Product Passport. Imagine a comprehensive data set that not only satisfies UFLPA, but also provides unimpeachable ESG data like carbon footprint, water use, recycled material content and energy use . At this point you’ll be calculating Scope 3 Life Cycle Assessments for every item and using AI to look for opportunities to improve it.

The highest level of maturity means full compliance with ESG legislation. It involves all the outcomes we talk about when a company has embraced sustainable business practices as part of its strategic mission rather than just an ad campaign, including an annual report on sustainability progress in the supply chain and clear targets for reducing GHG emissions.

Logility: Final thoughts?

Mark: While these higher stages are clearly a stretch for most companies today, don’t let that create inertia. You can roll out simple data collection in 30 days. Focus first on verifying the chain of custody for at-risk products, then build from there. You don’t need to hire a small army to gather the relationship data needed for the initial mapping. Tier 1s should take on the lion’s share of the work. They have your POs and they are selecting the suppliers.

You can learn more about how to achieve traceability and ESG compliance in Mark’s webcast ‘Demystifying Traceability’. Watch the webcast on demand here.