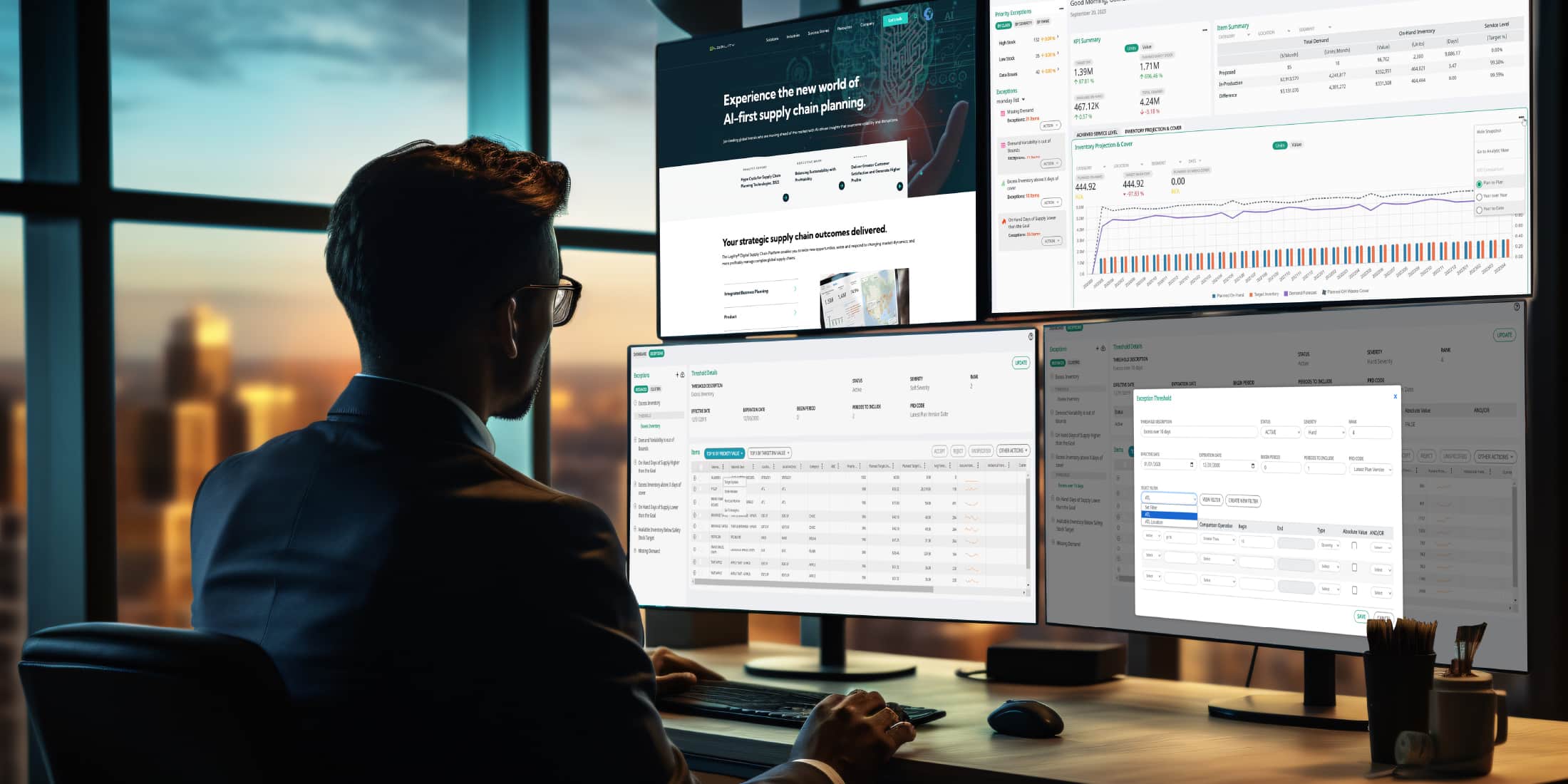

Optimize inventory with AI first scorecards

Today companies suffer from overstocks, stock outs, and poor service levels as they struggle to effectively manage inventory across an exploding number of products with outdated legacy systems. These performance issues often result in increased lead times and limited visibility for measuring and managing inventory KPIs.

Customer Success with InventoryAI+

One of the largest furniture manufacturers in the world improved inventory turns by 36% and reduced lead time by 30%, driving improved customer service levels.

Read Case StudyGet real time alerts that provide immediate visiblity

Gain instant insights into inventory performance, identify exceptions, and prioritize actions based on their impact and achieve:

- Reduced Inventory: Significantly lower inventory levels without compromising service levels.

- Improved Service Levels: Meet customer demands more consistently by avoiding stockouts.

- Increased Profitability: Optimize inventory investments for maximum return.

- Faster Time-to-Market: Quickly respond to market changes and disruptions.

- Enhanced Decision Making: Leverage AI-driven insights to make informed decisions.

Beyond these immediate benefits, MEIO enhances the agility of the supply chain, enabling businesses to swiftly adjust and respond to market fluctuations and maintain adequate inventory levels throughout their network, thereby securing operational resilience and adaptability.

Check Out Logility’s Generative AI Solution, Logility Expert Advisor (LEA)

Logility’s generative AI solution, Logility Expert Advisor (LEA) optimizes planning, manages supply chain complexities, and enhances financial performance. With LEA’s conversational interface and integration with large language models get actionable insights to bridge departmental silos and accelerate decision-making.

Use LEA for things such as:

- Achieving higher efficiency & visibility in planning

- Demand and supply imbalance causality

- Real-time supply chain adjustments

Service Parts Management: The Linchpin to Successful Service Operations

Learn how Service Parts Planning and Optimization (SPP) drives successful post-sale support, boosts profits, and secures customer loyalty, all while managing the challenges of intermittent demand.

Read Now