As AI advances in the 2025 Gartner® Hype Cycle™, four innovations are turning supply chain planning volatility into a proving ground for intelligent business operations. Technology is allowing companies to leverage resilience into opportunities.

The rules of supply chain planning are being rewritten in real time. From Red Sea shipping disruptions that are rerouting global freight to rising tariffs and shifting labor markets, volatility has become the new baseline. And despite advancements in visibility, many companies still find themselves reacting too late, too often, with outdated tools that weren’t built for today’s pace or complexity.

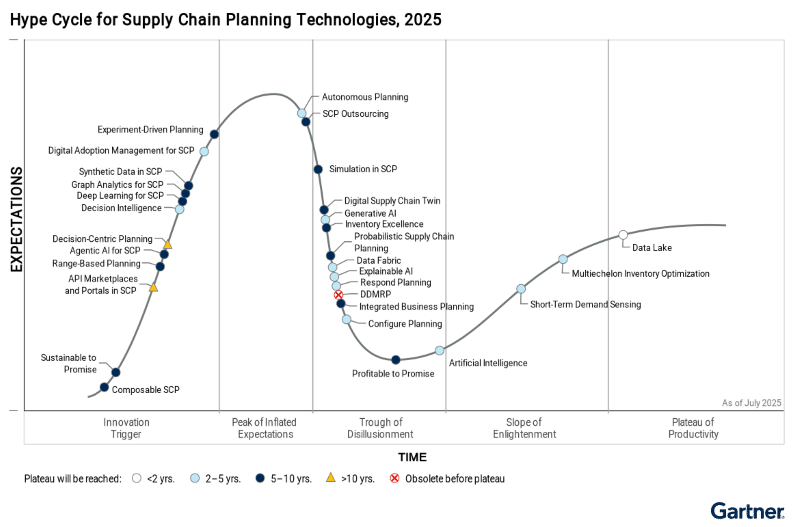

The 2025 Gartner® Hype Cycle™ for Supply Chain Planning Technologies could not have come at a more critical moment. This year, four innovations stood out in the report: two are here and available now (explainable AI and autonomous planning), and two we believe will flow through the hype cycle at lightning speed (agentic AI and decision-centric planning). Each delivers breakthrough potential – but together, they lay the groundwork for a more intelligent, resilient, and future-ready supply chain.

However, hype doesn’t always translate to long-term impact. Not every trend sticks, and not every innovation is ready to scale. The real opportunity lies in investing where AI can drive intelligent supply chain planning with improved agility, transparency, and trust.

What’s Here: Explainable AI—Making Intelligence Understandable

AI isn’t helpful if no one understands what it’s doing. That’s why explainable AI (XAI) is essential for adoption. Leaders need to know why a forecast changed, what data influenced it, and how much confidence to place in it. More importantly, they need models that don’t just predict but also explain.

This level of clarity is especially critical in demand planning, where even a slight anomaly can ripple across procurement, manufacturing, and customer service.

With explainable AI, planners can dissect forecasts into meaningful components such as baseline, seasonality, trends, promotional impacts, and external events. Then, they can validate assumptions, adjust inputs, and communicate decisions clearly to stakeholders.

Meanwhile, in heavily regulated industries or organizations managing global supply chains, explainability is quickly becoming a business requirement. The ability to audit decisions, trace inputs, and defend outcomes is foundational to trust, accountability, and strategic execution.

This transparency that explainable AI offers also makes collaboration easier. When supply chain, finance, and commercial teams are aligned around the same data-driven story, it reduces friction and drives faster consensus. It also empowers newer planners who may not have years of domain expertise but can learn from the system’s logic and apply it effectively.

And here’s the best part: explainable AI accelerates the adoption of AI. Teams are more likely to act on the information technology offers when they trust the output. And over time, that trust emerges as the foundation for scaling AI across the entire enterprise.

What’s Here: Autonomous Planning—Moving from Reactive to Resilient

Autonomous planning is moving beyond the peak of inflated expectations, according to Gartner’s hype cycle. But that descent isn’t a decline – it’s a signal of maturing potential. The spotlight is shifting from theoretical promise to actual proof, as supply chain teams begin to integrate autonomous capabilities into daily workflows.

At its core, autonomous planning is about minimizing manual intervention. It automates routine decisions, shortens response times, and delivers higher forecast accuracy by eliminating latency in the planning process. In volatile markets, that kind of speed is a competitive edge.

The value of autonomous planning becomes clear when plans can adapt quickly and efficiently. Imagine a promotional spike triggering unexpected demand. Rather than scrambling to re-forecast and reallocate inventory, autonomous systems detect the shift, rebalance resources, and surface new supply plans before planners even intervene. These real-time pivots turn disruption into responsiveness.

Such autonomy can be empowering to employees because it enhances control, rather than diminishes it. Teams can curate system-generated recommendations to inform their decisions, avoiding the need to build plans from scratch or react to yesterday’s data. This experience includes adjusting thresholds, evaluating assumptions, and focusing on exceptions that require human insight.

Organizations with autonomous planning already embedded in their sales and operations planning (S&OP) workflows are experiencing tangible benefits, particularly in demand sensing, scenario planning, and promotional forecasting. These processes are becoming increasingly connected, adaptive, and self-adjusting, allowing people to spend less time on low-value activities and have more bandwidth to focus on strategic initiatives.

Still, adoption takes data readiness, process alignment, and cultural change. Teams must shift from being doers to validators, from chasing down issues to anticipating them. But with autonomous planning, many companies are already undergoing this transition by establishing clear goals, piloting manageable use cases, and building trust in the system’s recommendations before scaling further.

What’s Coming: Agentic AI in Supply Chains—Sparking Intelligent Action

There was a time when AI simply learned. Then came generative AI, which produces marketing content, writes emails, and helps developers code faster. And now, we welcome Agentic AI to the fold. And while this is early in the innovation trigger, Logility believes this is one of the quickest innovations to move through the hype cycle.

Agentic AI in supply chain environments marks a turning point for generative AI. These autonomous software agents can reason, plan, and execute multistep workflows without human supervision. Unlike their AI predecessors, agentic systems interpret live data, respond to dynamic conditions, and coordinate across functional silos with speed and precision. This is where the gap between insights and execution begins to disappear.

Inherently complex, distributed across partners and geographies, and continuously subject to disruption, supply chains are an ideal proving ground for this shift. Take, for example, a container delayed at a port in Asia. Instead of simply flagging the issue, an agentic system models alternative scenarios, reroutes inventory, updates the customer in Europe, and initiates fulfillment from another location. What may look like a simple fix involves dozens of decisions, coordinated across time zones and systems – all of which agentic AI does autonomously, simultaneously, and immediately.

Various supply chain organizations worldwide are already using this AI advancement. Specialized agents, such as the Logility Expert Advisor, understand business context, connect to real-time data, and surface KPIs and context-rich, decision-ready insights tailored to the user’s role.

That said, agentic AI should not replace people in the workplace. It augments human work by reducing the daily noise of one-time disruptions and surprises, removing process friction, and shifting planners, executives, and customer-facing teams from decision-making and firefighting to orchestration, strategy, and innovation.

However, organizations first need to see value before fully adopting the technology. That’s why high-confidence use cases – including replenishment planning and demand signal validation – are recommended before expanding to more complex scenarios over time. As trust builds incrementally, so does the power of agentic AI.

What’s Coming: Decision Centric Planning–Reducing the Latency from Strategy Through Execution

As technology evolves, companies are pushing the boundaries of traditional supply chain processes, especially in S&OP. The ability to reduce latency in decision-making will open doors for companies to evolve S&OP into a true strategic driver of their business. Software solutions designed to tie together all levels of business (strategic, planning, execution), continuously monitor the digital twin to recognize disruptions, and leverage AI to identify risk and opportunities will expedite competitive advantage.

The true value of decision centric planning is the ability to configure and recognize opportunities in real time, answering questions like:

- If a key competitor has a disruption, what is the plan for the company to take advantage of the opportunity?

- Is there extra capacity within our production capabilities?

- Can we run a promotion in a timely and cost-effective manner?

- How do we leverage learning opportunities from the past to plan and predict the future?

- How does AI detect and serve up these opportunities?

- And if disruption happens to us, how do we identify the risk and respond to limit the impact?

When we talk about developing a true anti-fragile supply chain, the ability to take advantage of disruptions moves beyond operations. It involves all levels of the organization and requires a level of real-time actions that are not possible in traditional S&OP processes. All levels of the organization need to have the ability to act and coordinate as soon as the risk is detected or the opportunity is identified.

Decision centric planning will leverage all technology, including autonomous planning, GenAI, and agentic AI to remove the inherent data latency in today’s processes. Agents can be deployed to automate responses and track courses of action. GenAI can monitor and explain the results of the actions suggested. Autonomous planning executes mundane tasks and empowers strategic decision-making across the organization.

Plan Ahead, Instead of Catching Up

Supply chain planning is at a strategic inflection in its AI adoption. Agentic AI, autonomous planning, and explainable AI are interdependent levers of change, not individual trends.

The 2025 Gartner Hype Cycle captures this shift from reactive workflows to intelligent orchestration. There’s notable tension between what’s emerging and what’s actionable, between experimentation and execution. While not every technology delivers on its promise, those that do – such as agentic AI, autonomous planning, and explainable AI – are already unlocking value.

Intelligent supply chain planning starts with strategic investments in the right innovations, at the right time, for the right outcomes. They give planners superpowers without removing their judgment, while enabling organizations to thrive through constant change.

The companies that win in this new era of AI won’t be those that react the fastest. They’ll be the ones with the clarity to cut through the noise, the courage to invest early, and the control to steer confidently into the future.

Download the 2025 Gartner® Hype Cycle™ for Supply Chain Planning Technologies to see where your team can start – and how Logility can help you lead.

Written by

Scott Tillman

SVP, Innovation

Short bio

With over 25 years of experience, Scott Tillman drives supply chain innovation at Logility. His experience includes business process reengineering of supply chain operations and ERP implementations for Fortune 500 companies in the high-tech, process manufacturing, retail, and healthcare industries. His leadership roles within software companies range from product management to engineering, focusing on the development of supply chain solutions specific to inventory replenishment, demand forecasting, and distribution management.