One of America’s largest private-label cheese producers trades in spreadsheet-driven inefficiencies for a smarter, faster, and more resilient operation.Headquartered in Hiram, Ohio, Great Lakes Cheese (GLC) has spent more than 65 years building a reputation as a trusted partner to retailers, foodservice providers, and ingredient buyers. Though the brand rarely appears on store shelves under its own name, its products are everywhere—from slices for summer cookouts to shreds topping family casseroles.

“We are stacked with opportunity,” Davis Shumaker said with a smile during a recent webinar hosted by Logility. “Pretty much wherever you find cheese, it’s likely you’ll find one of our products.”

As a Senior Manager of GLC’s Supply Chain Planning organization, Shumaker has seen the company expand into a national network strategically positioned to deliver the lowest landed cost to customers. However, this growth story is not only about scale, but also about an ownership culture that drives accountability and pride throughout the workforce.

Advancing a Quiet Giant’s Growth Agenda

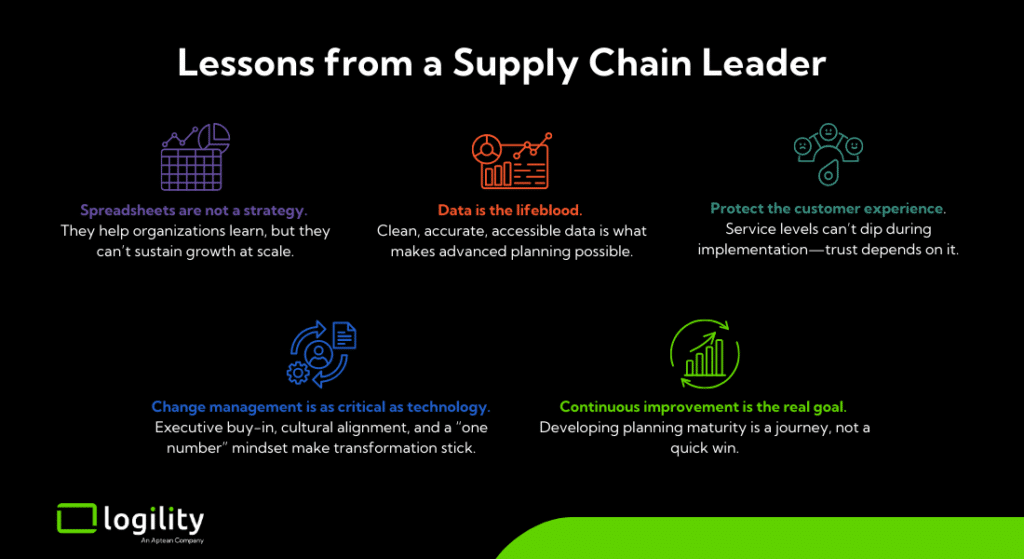

For decades, Great Lakes Cheese relied on what so many companies still do today: spreadsheets. It wasn’t unusual in the early days. Microsoft Excel was flexible, accessible, and familiar. But as the business grew, the limits became obvious.

“When I joined the company eight years ago, there was no sales and operations planning process,” Shumaker admitted. “Everything was planned by gut feel. We did as good a job as you can with Excel, but everything was manual, it was slow, and ultimately we couldn’t execute.”

With 10 facilities, more than 4,500 employees, and over 6,000 SKUs shipped nationwide, the situation was far from sustainable. Customers expected near-perfect service levels, while SKU lifecycles became increasingly complex and capacity constraints intensified.

“We saw the challenges coming, but we couldn’t do much to mitigate them,” recalled Shumaker. “It was like watching a train coming down the tracks.”

Forecasting often relied on seasonal intuition rather than data science. Summer holidays meant slices for burgers, Thanksgiving and Christmas brought surges in shredded cheese and snack trays, and the Super Bowl meant queso dips and blocks. Without a modern planning system, anticipating and meeting those waves of demand was a matter of guesswork.

That moment of realization—when speed and visibility became non-negotiable—was the spark that led GLC to reimagine its entire supply chain planning foundation.

Choosing a Partner to Build a Resilient Foundation

Recognizing that spreadsheets could no longer carry the weight of a multibillion-dollar supply chain, Great Lakes Cheese set out to find a partner that could match both the scale of its operations and the speed of its ambitions. The choice was Logility.

“The goal of bringing in Logility was to engrain it into the fabric of the business for the long term,” Shumaker explained. “That way we could build our processes around the functionality of the tool and maximize its value.”

GLC implemented four core supply chain functionalities in the Logility Decision Intelligence Platform:

- Demand optimization to provide statistical forecasting models that replace gut feel and spreadsheets, improve accuracy across thousands of SKUs, and increase confidence to plan weeks in advance

- Inventory planning to help balance lean inventory levels with high service expectations, ensuring the company can sustain a 99% fill rate while holding finished goods for fewer days

- Supply planning to align production capacity with demand requirements across plants, giving visibility into constraints, and enabling more flexible sourcing across the network

- Integrated business planning to create a single version of the truth for cross-functional alignment and decision-making

Together, the functionalities provided the visibility and structure that the company had been missing. Suddenly, forecasts weren’t debated anymore. Instead, they were shared across finance, sales, and operations.

Planning no longer ended at visibility; it became actionable. But that change didn’t happen overnight.

Integrating ERP systems with the new platform took iteration and persistence. More importantly, a mindset shift was needed to prioritize the assurance of clean data and cultural adoption. At first, executives, planners, and plant managers were cautious. But over time, they began to see the benefits of aligning around a single number, process, and vision for the business.

Perhaps most impressively, the transformation happened without disrupting service. “Our customers wouldn’t accept the excuse, ‘Sorry, we missed your order because we’re implementing new planning software,’” remarked Shumaker. “We had to protect the business and protect our customers’ and vendors’ trust.”

And the gamble paid off. Forecast accuracy climbed to 80% across all SKUs and 85% for high-volume items. Weekly deviations in volume dropped to a razor-thin margin between 0% and 3%. The planning team itself expanded from a two-person operation to a centralized group of six, evenly divided between demand and supply, but tightly integrated with sales and operations. Even service levels hover at an enviable 99%—an achievement made even more impressive by the company’s lean inventory strategy of just nine to ten days of finished goods.

For customers, the reliability of the supply chain became evident. The orders arrive, shelves stay stocked, and products are fresh. But for GLC, the real advantage lies in establishing the discipline, alignment, and vision to enable technology to reshape how the supply chain operates.

Letting the Results Speak for Themselves

Although impressive, the numbers only tell part of the story. The cultural shift has been just as important.

“We don’t have a different finance forecast, a different sales forecast, and a different operations forecast,” Shumaker explained. “The company has adopted one forecast as the forecast for the business. Everyone shares in the ownership of it.”

That alignment has broken down silos that once slowed communication and decision-making. Sales teams, operations leaders, and finance executives are now working from the same playbook. As a result, GLC responds faster to demand swings, manages inventory better, and runs a planning function that acts as a unifying force rather than a back-office necessity.

And the organizational change extends beyond the planning room. What started as a team of two has now grown into a six-person unit—demand and supply balanced equally—embedded throughout the company. “We’re ingrained with the rest of the organization,” Shumaker said. “On the demand side, we’re integrated with sales and customers. On the supply side, with our operations and plants.”

Entering the Next Chapter of Growth with AI and Agility

For Shumaker and his team, success is a continuous journey of building on what works, refining processes, and preparing for what’s next. “We know the road ahead has a lot of opportunity,” he said. “We’ve come a long way, but we can continue to evolve, get better, and grow. That’s really what this journey is about.”

Part of that evolution involves exploring artificial intelligence (AI). Demand sensing, predictive analytics, and automated scenario planning all offer the potential to sharpen forecasts and improve decision-making. And sometimes, the signals come from unexpected places.

“Surprisingly, TikTok influences cheese sales,” Shumaker noted. Viral recipe videos have shifted seasonal demand patterns, with bar cheese now driving holiday spikes where shredded cheese once dominated. How do we leverage AI to understand those trends and predict their impact? That’s the next big opportunity.”

At the same time, GLC is focused on optimizing its complex manufacturing and distribution network. With some products produced at multiple facilities and others limited to single-source lines, balancing redundancy and efficiency remains a constant challenge. However, dynamically allocating production and inventory across plants can unlock new gains in the company’s cost efficiency and service reliability.

While machine learning isn’t yet embedded in their forecasting models, Shumaker believes it’s only a matter of time. “We have very strong statistical models today,” he said. “But as the data matures, there will absolutely be opportunities to leverage machine learning in meaningful ways.”

Reimagining What’s Possible in the Dairy Aisle and Beyond

By moving from gut feel and manual spreadsheets to an integrated, technology-enabled supply chain, GLC has rewritten the rules for how a traditional manufacturer can operate with agility. Its journey shows that resilience is much more than avoiding disruption—it’s about building the systems and culture that let you adapt, respond, and thrive in the face of it.

For supply chain leaders everywhere, the challenge is universal: speed and visibility are no longer optional. The companies that succeed will be the ones willing to reimagine their foundations—just as Great Lakes Cheese did.

Want the full story?

Watch the webinar on demand to dive deeper into Great Lakes Cheese’s transformation journey—complete with behind-the-scenes insights and practical strategies.