Manufacturing execution is the key to turning production challenges into competitive advantage.

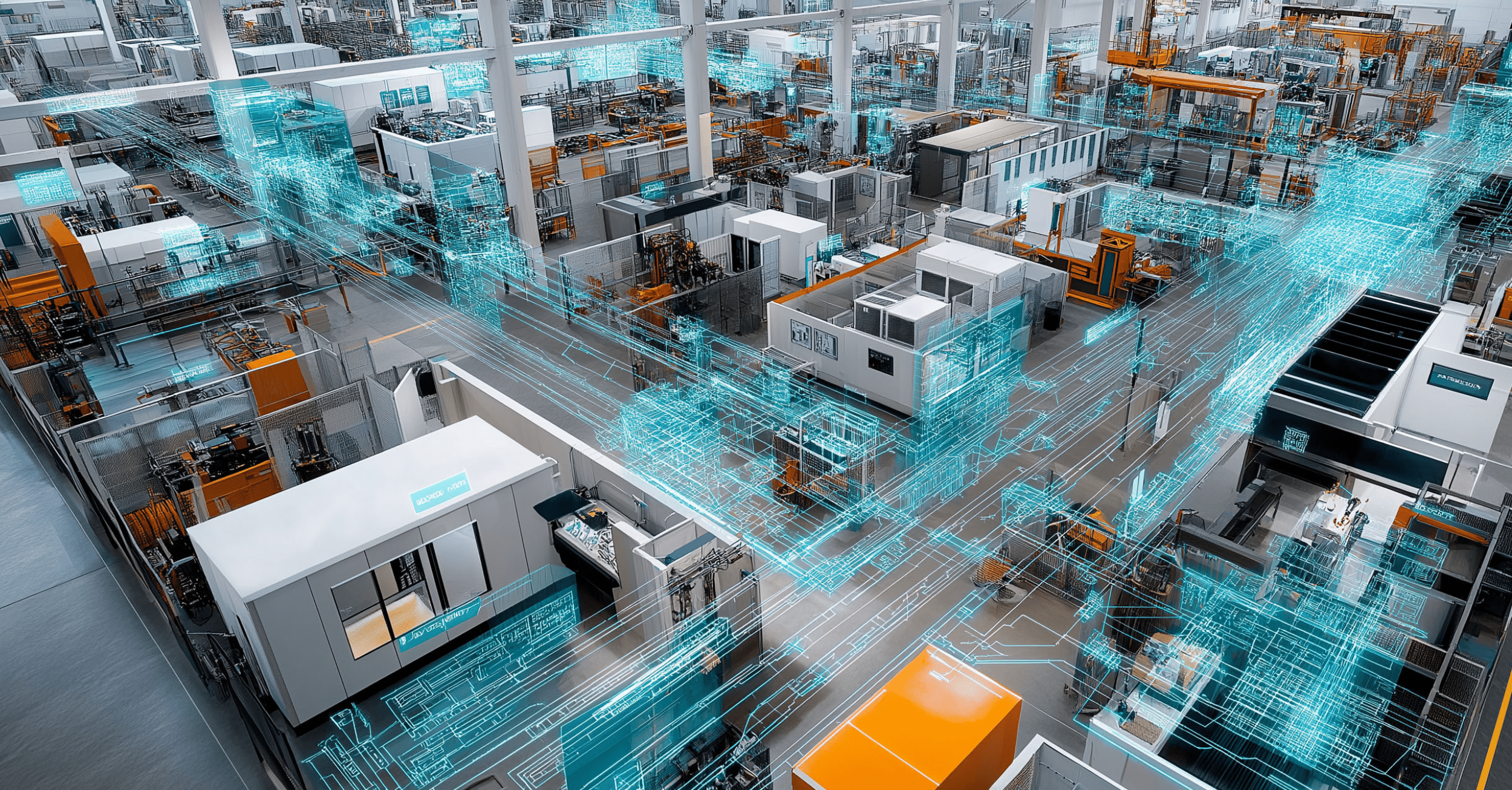

Today’s manufacturers struggle with disconnected systems, unpredictable downtime, and limited visibility across the shop floor. A Digital Factory approach solves these pain points by connecting every process, resource, and machine in real time—giving you the transparency and control you need to act fast. With intelligent data insights and automated workflows, you can reduce waste, boost efficiency, and deliver on time, every time. It’s not just digitization—it’s a smarter way to execute and win.

Your Factory, Digitized for Maximum Performance

The Digital Factory brings every part of your production process together—connecting people, systems, and data for maximum efficiency. From planning to execution, it solves your biggest challenges with real-time visibility, automation, and control.

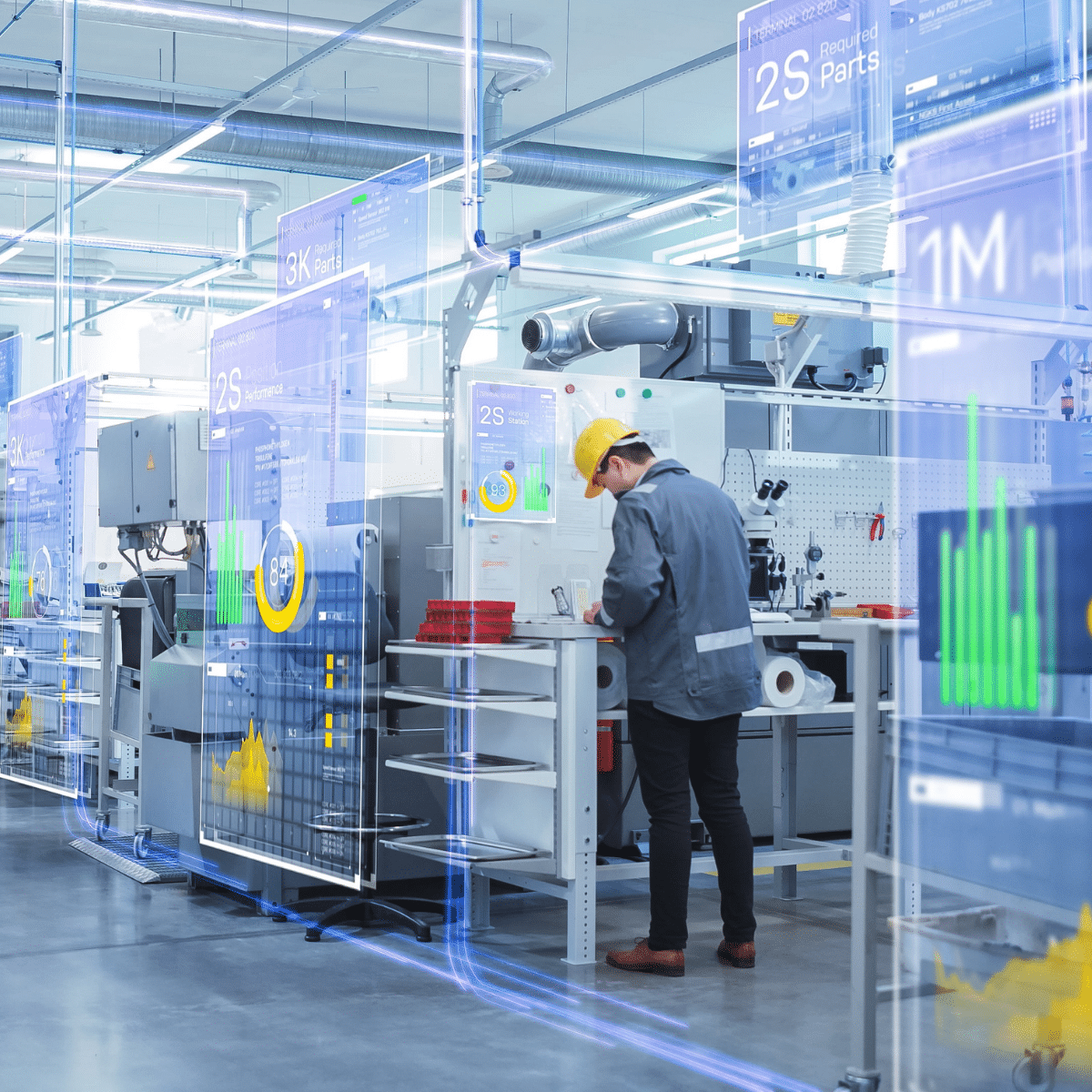

Connected

Worker

Reduce audit costs by over 50% with tools for shift and staff management, checks, and asset tracking.

Quality

Management

Cut waste by more than 80% through statistical process control, lab information systems, and non-conformance management.

Production

Management

Improve operational efficiency by 25% with MES, track-and-trace, and total productive maintenance.

Planning and

Scheduling

Increase capacity utilization by 30% using material and capacity planning, scheduling, and energy optimization.

Your Next Step Toward Operational Excellence.

Disconnected systems and manual processes are holding you back. Our Digital Factory approach helps you plan smarter, execute faster, and deliver with confidence.