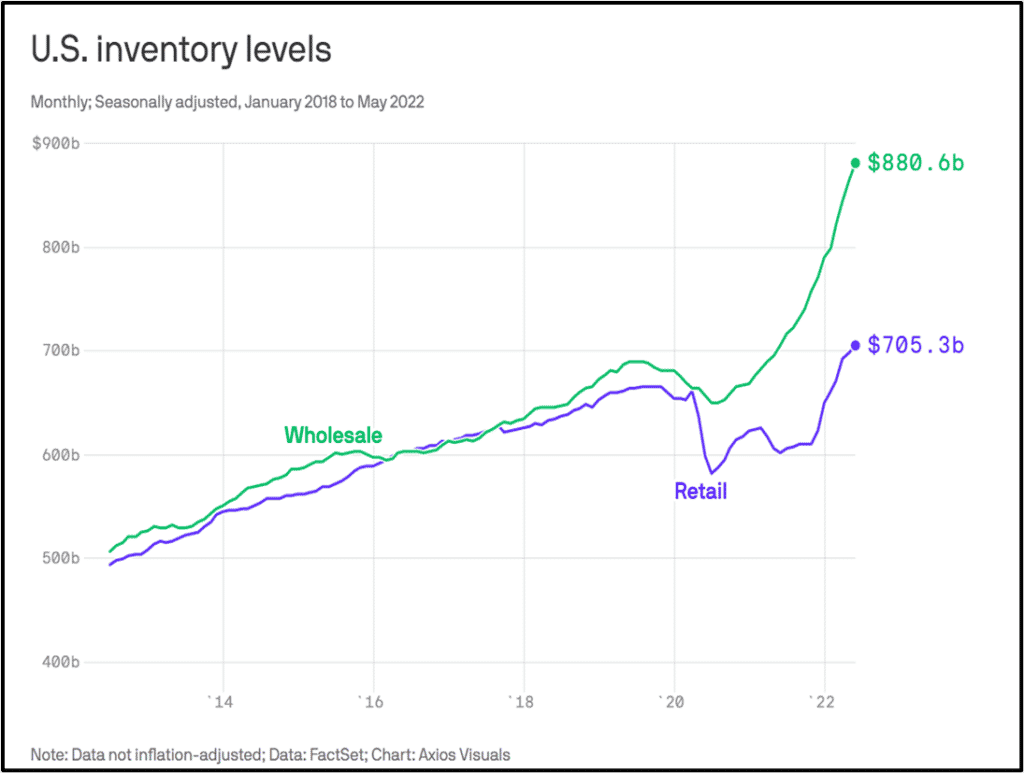

The traditional formula of minimizing costs and maximizing efficiency is no longer enough – instead, tradeoffs need to be made. Higher costs are an unfortunate reality in the current supply chain environment, and they’re likely to persist despite attempts to contain costs in areas that can be controlled.

This realization for supply chain leaders creates new questions about which strategies can genuinely optimize their operations while offsetting changing demand and supply disruption. Of course, they know resilience is needed to succeed in today’s dynamic business environment. But it’s also well understood that intelligent decision-making that drives always-on, dynamic, and flexible supply chain planning is equally critical.

With a supply chain network design and optimization solution, businesses can find a significant advantage in balancing the variables that get in the way of optimizing complex supply networks and stabilizing product flows.

Five Reasons for Adopting a Supply Chain Network Design and Optimization Solution

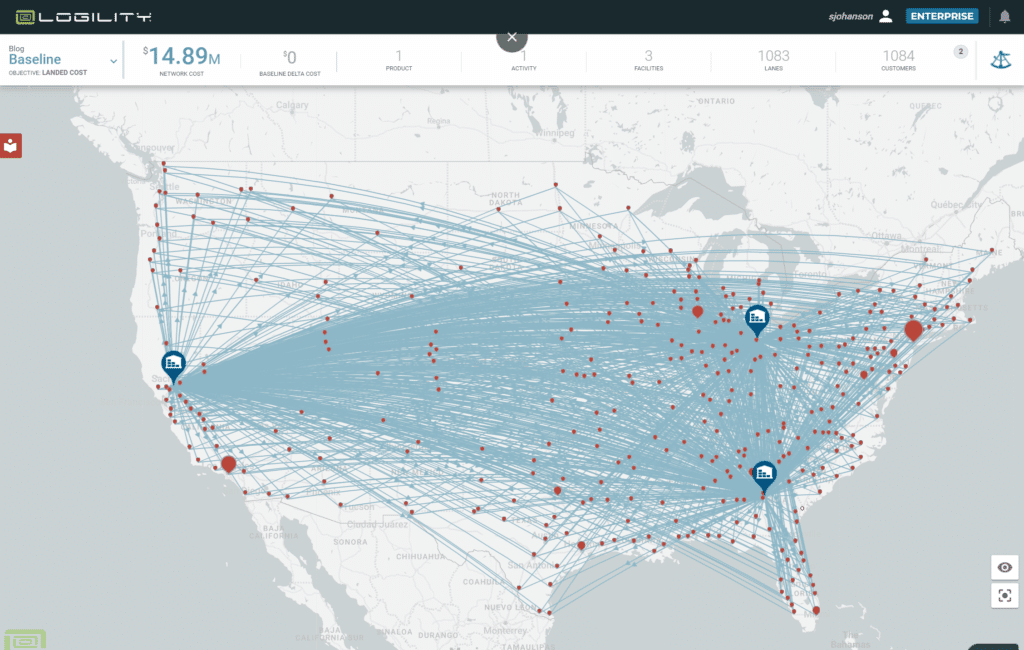

Suppose a product can be manufactured in multiple plant locations, and there’s a potential warehouse only 50 miles away from 60% of your customers that regularly order it. How would you know if the revenue potential of shifting locations outweighs any cost savings or increases – or better yet how are your logistics activities impacted?

Often, businesses do not have a clear-sighted way of determining whether such an optimization tactic is beneficial, especially at the moment the opportunity arises. Instead, supply chain leaders must wait for their executive team to sign off on the suggestion after months of financial analysis – and lost potential for revenue growth.

However, the adoption of a supply chain network design and optimization solution can change the outcome for five reasons:

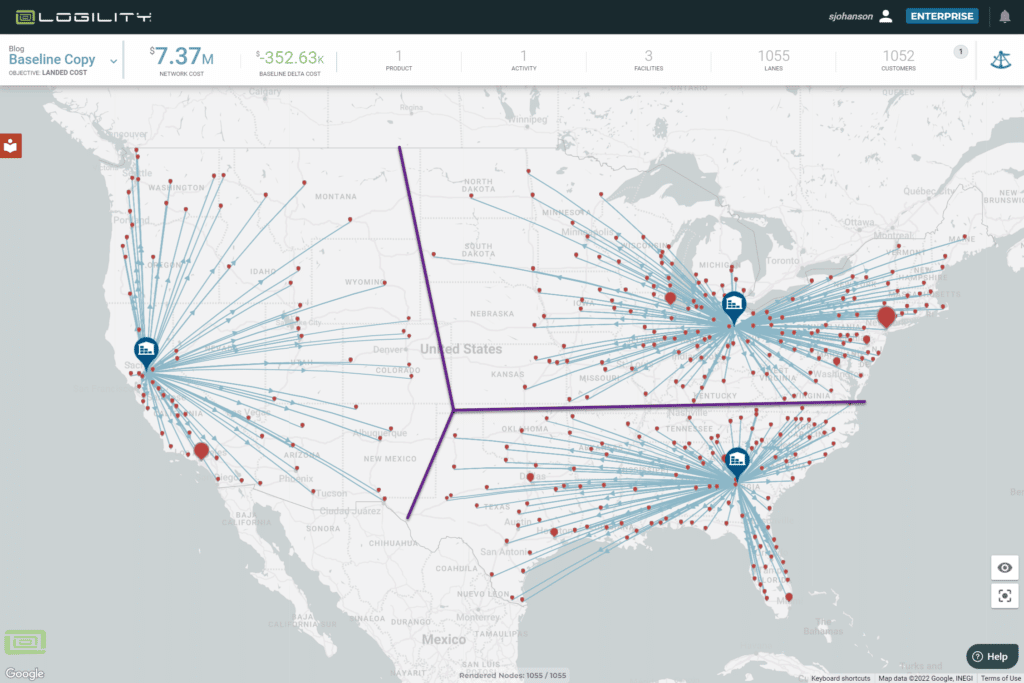

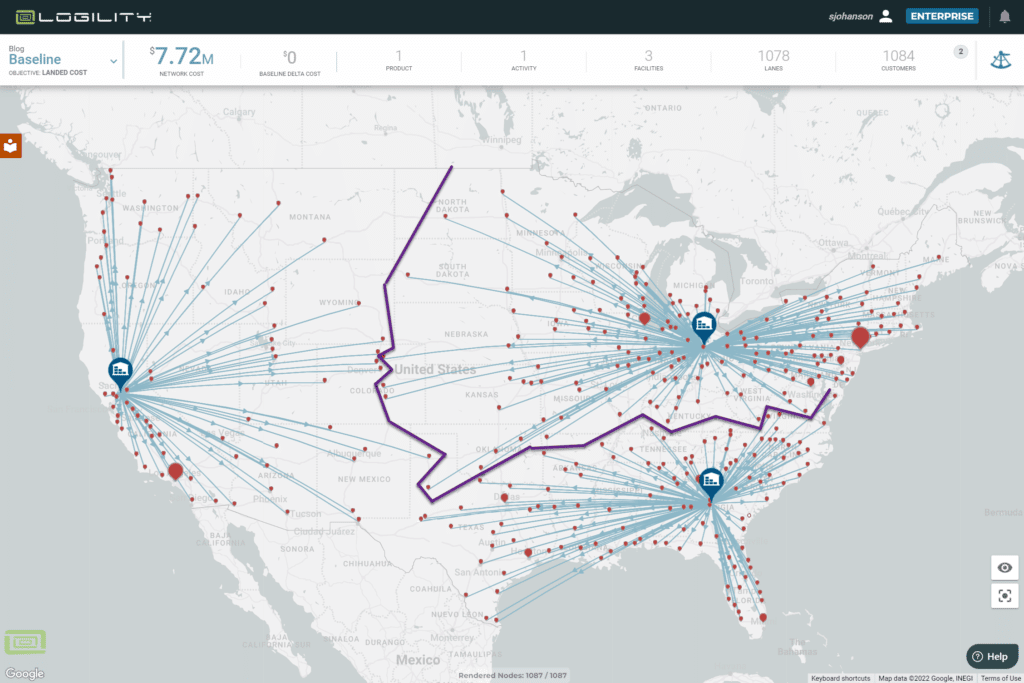

First: Comprehensive and credible insights. When information and insights come from a place of credibility, getting buy-in from executive leadership, business partners, and even the sales and marketing organizations is easier to accomplish. A solution that brings together data from across the business ecosystem and visualizes it in a compelling way from a common environment provides a consistent source of truth that keeps everyone in your organization on the same page. As a result, the entire enterprise can be fully educated on the latest opportunities and risks in demand, supplies, costs, and goods movement performance and make actionable decisions that deliver optimal outcomes.

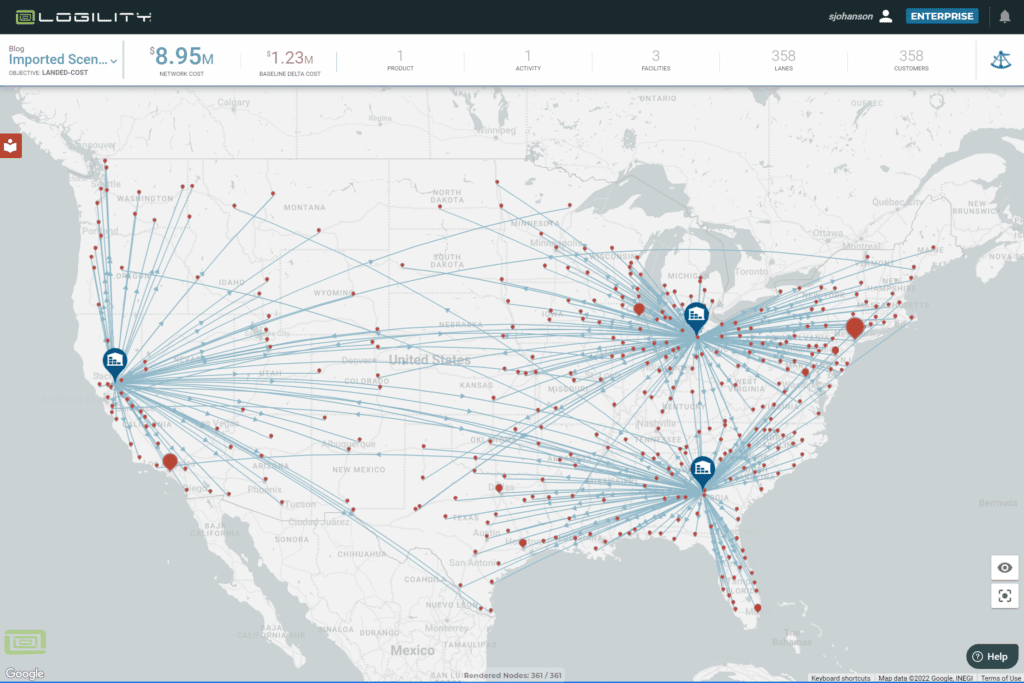

Second: Real-time analysis and visualizations. A supply chain model created and set on the back burner six months ago cannot be picked up, dusted off, and acted on. Market dynamics change, and the model needs to be redesigned and deliver value just as quickly – instead of in weeks or months. Predictive analytics and data visualization based on near-real-time enterprise data can help determine the feasibility and outcome of the original model and uncover any shift in plans that can further optimize operational efficiency and revenue growth.

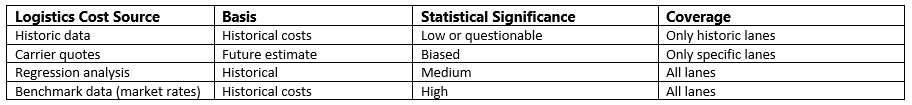

Third: Repeatable network design. A reference database and benchmarking tools eliminate the need to build a new model from scratch every time while leveraging your company’s current and forecasted demand with near-real-time access to information. Repeatable network design means time and cost savings; in fact, 10-20%1 in operating costs can be saved when network modeling becomes a routine activity rather than an event that happens once every three years.

Fourth: Integration across a common digital platform. The goal of supply chain integration is to support the seamless exchange of information across all network tiers; through planning, resource management, execution, and measurement, and throughout the product lifecycle. Being tightly coupled to a digital planning platform, a supply chain network design and optimization solution can form a close working relationship focused on improving response, accelerating production time, and minimizing cost and waste.

Fifth: Ease of use. The solution brings decision-making around sourcing, production, and logistics further down the organizational chart. All roles – from supply chain executives to data scientists and analysts – can leverage business-wide information and intuitively build data visualizations to get accurate insight on whether you should move forward, how to improve your negotiating position, and when is the best time to start. In addition, your business can reassess its decisions as market dynamics change.

The Start of a Powerful Era in Supply Chain Design

The more global supply chains are under stress, the more pressure to optimize the entire network from all sides. Clearly, it’s time for a holistic approach centered around comprehensive and trustworthy insights, real-time analytics and visualization, up-to-date reference databases and benchmarking, and a platform that enables integrated processes, collaboration and decision-making.

But the concept is not to tear down the supply chain. Instead, with network design and optimization, your business can evolve the ecosystem whenever and wherever it needs to transform, to meet customer expectations while fulfilling business demand for genuine optimization for the long term.

Connect with our supply chain specialists today to understand more about optimizing your supply chain by answering complex questions and making decisions faster.

1. CSCMP EDGE Leadership Panel Survey, 2022